UL材质证明

我司供应给深圳市XX有限公司的VHD-XXX 全套塑胶外壳,均符合UL要求。如不符合,我司承担相应后果。并附上UL证书(PC ABS )

深圳市XXX公司 2014-05-09

第二篇:467 材质证明

3

?

High Performance Adhesive Transfer

?

Tapes with 3MAdhesive 200MP

Technical Data

March, 2001

Product Description

3M?adhesive 200MP is a popular choice for graphic attachment and membraneswitch applications because it has excellent quality, consistency and durability. Inaddition, as a result of 3M’s innovative, proprietary process, 3M adhesive 200MP alsooffers the following excellent performance characteristics.

Clarity (virtually free of vapor inclusions that are commonly found in adhesivesproduced by the traditional solvent coating technique).

Excellent high temperature performance as well as excellent shear strength (thatminimizes edge lifting and slippage of parts).

Excellent resistance to harsh environments; this adhesive can withstand splashes oforganic solvents, weak acids and bases and salt water, cleaning solutions, germicidals,disinfectants, oils, etc. In addition, it performs well after exposure to humidity andhot/cold cycles.

Provides some initial repositionability when bonding to plastic parts (not metal). Thisallows graphic parts to be lifted and repositioned if initial alignment is incorrect.Finally, this adhesive family is provided with a variety of liner configurations to helpensure excellent process flexibility.

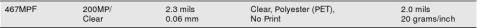

Constructions

ProductNumberAdhesiveType/Color1200MP/Clear200MP/ClearAdhesiveThickness2(mils, mm)5.2 mils0.13 mm

5.2 mils0.13 mmLiner

Color, Type,Print

Tan, 58#, Polycoated Kraft,“Scotch? 468MPHiPerformance Adhesive”Clear, Polyester,No Print

LinerCaliper3/

Liner Release4

4.0 mils

50 grams/inch2.0 mils

20 grams/inch

468MP

468MPF

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MP

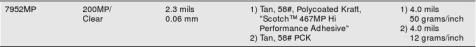

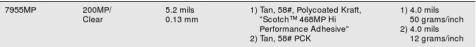

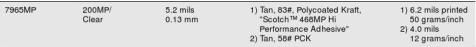

Constructions (continued)

ProductNumberAdhesiveType/Color1AdhesiveThickness2(mils, mm)Liner

Color, Type,Print

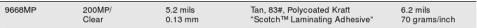

1) Tan, 83#, Polycoated Kraft,“Scotch? 467MPHiPerformance Adhesive”2) Tan, 58# PCK

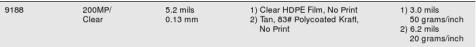

1) Clear HDPE Film, No Print2) Tan, 58# Polycoated Kraft,No Print1) Clear HDPE Film, No Print2) Tan, 58# Polycoated Kraft,No PrintTan, 83#, Polycoated Kraft

“Scotch? Laminating Adhesive”1) White Polypropylene (PP),No Print

2) Tan, 58# Polycoated Kraft,No Print

LinerCaliper3/

Liner Release4

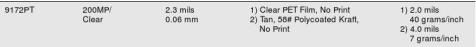

1) 6.2 mils printed50 grams/inch2) 4.0 mils

12 grams/inch

1) 3.0 mils

50 grams/inch2) 4.0 mils

7 grams/inch1) 3.0 mils

70 grams/inch2) 4.0 mils

7 grams/inch6.2 mils

60 grams/inch1) 3.5 mils

45 grams/inch2) 4.0 mils

20 grams/inch

7962MP

200MP/Clear2.3 mils0.06 mm

9172MP

200MP/Clear2.3 mils0.06 mm

9185MP

200MP/Clear5.2 mils0.13 mm

9667MP9676

200MP/Clear200MP/Clear

2.3 mils

0.06 mm2.3 mils0.06 mm

Note 1: The adhesive color is transparent with a very slight yellow cast. The yellow cast is not typically visible in a single

adhesive layer.Note 2: The thickness listed is based on a calculation from manufacturing controlled adhesive coat weights using a density of

1.012 g/cc. While past data pages have listed nominal thicknesses of 2 and 5 mils, the coat weight (and theoreticalcaliper) has not changed.Note 3: Where two liners are listed (double-linered products, useful for selective die-cutting), liner 1) is the primary (stays with

the die-cut part); liner 2) is the secondary (removed first). The polycoat on one side of the heavy linered products(83#) was changed to balance the liner. This balanced sheet will provide an improvement to the flatness of productsmade using the heavy liner.Note 4: Typical liner release value, in grams/inch, tested at 90 ipm.

For additional “double coated” product constructions (adhesive/carrier/adhesive) using 3M?adhesive 200MP, please refer tothe data page for 3M?Membrane Switch Spacers (70-0707-1195-0).

- 2 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MP

Constructions(continued)

Liner Configuration Guide:

General purpose steel rule die-cutting58# polycoated kraft (PCK)Steel rule cutting nested or multi-up nameplateson common sheet83# PCKKiss cutting, steel rule83# PCKRotary die-cuttingpolyester (PET)Selective die-cutting (cut adhesive before laminate)double-lineredThermoformingHDPE, white PPPart inspectionHDPE, PETEmbossed partswhite, PP, HDPEMetal parts (punch press)polyester or DKaddedThe polycoated kraft liners are more resistant to humidity curl and wrinkling than standardplain paper liners. The film liners are the most resistant to the negative effects of humidity.

Adding Liners for3M?Adhesive 200MP:

1.Rotary processing, adhesive only, on a densifiedoutside of 3M? liner 49945

kraft liner. In this process the adhesive will stay withthe 58# PCK liner, leaving adhesive die-cuts

dispensable from the 3M?densified kraft liner 4994.

2.Rotary processing for finished parts. It is most efficient toinside of 3M liner? 49945

use 3M?Adhesive Transfer Tapes 467MPF or 468MPF.If a densified kraft (DK) liner is necessary, the adhesiveshould be first laminated to the substrate with pressure.After lamination, remove the 58# PCKliner and laminate

the inside of the 3M?liner 4994 (DK). Current process limitationsprevent the supply of the 3M?adhesive 200MP on a DK liner.

Note 5: The outside of 3M?liner 4994 has the most premium silicone release (easiest release).

Typical release, of the outside of 3M?liner 4994, from 3M?adhesive 200MP afterlamination (both before and after heat aging) is 5-10 grams/inch. For slightly higher linerrelease, typical values for the inside of the 3M?liner 4994are 15-20 grams/inch whenlaminated to the 3M?adhesive 200MP.

Typical Physical

Properties andPerformanceCharacteristics

Note:The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

I. Adhesion to Stainless Steel

ASTM D3330 modified (90°peel, 2 mil aluminum foil backing)

Dwell

15 minute room temperature (RT)72 hour RT

72 hour 158°F (70°C)

72 hour RT - 180°peel, 2 mil al foil

2 mil (0.002 inches)5 mil (0.005 inches)ounces/inchN/100mmounces/inchN/100mm

478216877

519018484

66118181133

72129198146

II. Adhesion to Other Surfaces

ASTM D3330 modified (90°peel, 2 mil aluminum foil backing)

Dwell

72 hour RT aluminum72 hour RT ABS72 hour RT acrylic72 hour RT glass72 hour RT polycarbonate

72 hour RT rigid PVC(unplasticized)

2 mil (0.002 inches)5 mil (0.005 inches)ounces/inchN/100mmounces/inchN/100mm

776261805852

846867886357

1156867926569

12674731017176

- 3 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MP

Typical PhysicalProperties andPerformanceCharacteristics(continued)

Note:The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

III. Relative High Temperature Operating Ranges

Short term (minutes/hours)Long term (days/weeks)

400°F (204°C)300°F (149°C)

IV. Static Shear

ASTM D3654 - 1" x 1" sample area - aluminum foil to stainless steel

Minutes to Failure

Temperature70°F (21°C)200°F (93°C)350°F (177°C)450°F (232°C)450°F (232°C)

Load2000 grams1000 grams500 grams400 grams200 grams

2 mil10,000+10,000+10,000+

6010,000+

5 mil10,000+10,000+10,000+

7510,000+

V. Shelf Life of Tape in Roll Form

24 months from the manufacturing date whenstored at 70°F (21°C) and 50% relative humidity.

VI. Adhesion Retention after Immersion and Exposure (percent retention)

Control is 24 hour RT dwell on stainless steel, 2 mil al foil backing, 90°peel, 12 ipm

2 mil

Control adhesion value in ounces/inchgasoline - 1 hour RT immersionMEK - 1 hour RT immersionweak acid - 4 hour RT immersionweak base - 4 hour RT immersion

oil (10W30) - 72 hour, 120°F (49°C) immersionwater - 100 hours, 70°F (21°C)salt water (5%) - 72 hours, 70°F (21°C)

warm/humid - 7 days, 90°F (32°C) and 90% relative humidityUV cabinet - 30 days, 70°F (21°C)

101 oz./inch

89%64%86%84%146%105%105%131%147%

5 mil149 oz./inch

83%66%86%83%141%116%93%101%93%

Temperature Cycle - *Three cycles148%158%*One cycle is 4 hours, 158°F (70°C); 4 hours, -20°F (-29°C); 16 hours, 70°F (21°C)

VII. Low Service Temperature

The glass transition temperature for 3M?adhesive 200MP is -31°F (-35°C). Many

applications survive below this temperature (factors affecting successful applications include:materials being bonded, dwell at RT before cold exposure and stress below the TG [i.e.expansion/ contraction stresses, impact]). Optimum conditions are: bonding high surfaceenergy materials, longer time at RT before cold exposure and little or no stress below the Tg.Note 6: The 3M?adhesive 200MP is not recommended for low energy plastics (polypropylene,

polyethylene, powder coated paints). For these surfaces please refer to 3M?adhesives300, 350, 300LSE and 300MP. The 3M?adhesive 300LSE has been used morefrequently as the bond areas in applications become smaller. It offers the smooth, highperformance characteristics of the 3M?adhesive 200MP with higher adhesion to plastic.The 3M?adhesive 300LSE is ideal for polyethylene, polypropylene, powder coatedpaints and for applications where the bonded area to plastic is less than 1/2" wide.

- 4 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MP

Electrical, Mechanicaland Thermal Properties

Note:The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

Property

Insulation Resistance (test voltage = 100 VDC)Mil-I-46058CDielectric Strength – (500 vac, rms [60 hz/sec])ASTM D149-92Breakdown Voltage

Dielectric Constant (at 1 KHz)ASTM D 150-92Dissipation Factor

Tensile Lap Shear – Peak LoadASTM D1002-72

(0.5 square inch on #6061 aluminum)Tensile Lap Shear – Peak StressASTM D1002-72Tensile Strength and ElongationASTM D2370-82

Thermal Conductivity

(ASTM C 518, results listed are at 109°F)Coefficient of Thermal Expansion - first heatASTM D 696 - second heat

0.098 BTU-ft/ft2-hr-F0.17 watt/m-K28 x 10-5m/m/C72 x 10-5m/m/C2 mil, 200MP(467MP was tested)>1 x 1010ohms880 volts/mil1,760 volts

3.400.021

5 mil, 200MP(468MP was tested)>1 x 1010ohms600 volts/mil3,000 volts4.060.02255 lbs.

109 PSI51 PSI1915%0.101 BTU-ft/ft2-hr-F0.18 watt/m-K-6 x 10-5m/m/C92 x 10-5m/m/C

Specifications

Please specify a) 200MP, 2 mil or b) 200MP, 5 mil rather than the exact productnumber based on the liner configuration. The converter will select the product withthe necessary liner configuration to meet the delivery requirements.3M?adhesive 200MP meets the following customer specifications:

2 mil

Coat weight7(grains/4" x 6")

(grams/ft2)Face Adhesion8(exposed side)

ounces/inchBack Adhesion8(liner side)

ounces/inch

14 ±12%5.4 ±12%30 minimum30 minimum

5 mil32 ±12%12.4 ±12%37 minimum37 minimum

Note 7: The amount of adhesive supplied, for pressure-sensitive adhesives, is controlled by

the adhesive coat weight, not the adhesive caliper. Pressure-sensitive adhesives arecompressible which results in high error for caliper measurements. The caliper listedin the Constructions section (page 1) has been calculated using a density of 1.012g/cc (testing caliper is not part of the standard release testing because of the errordescribed.)Note 8: ASTM D3330, 15 minute dwell on stainless steel. For this adhesive family, the adhesion

will be much higher with longer dwells on stainless steel and other high surface energymaterials (please refer to the typical Physical Properties section in this document to seeperformance on other materials after longer dwells).

- 5 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MP

Available Sizes

467MP468MP467MPF468MPF7952MP7955MP7962MP7965MP9172MP9185MP9676MP9667MP9668MP9188

MasterSize48", 54"60"54"48"

Slit Width(minimum)1/2"1/2"24" x 36"sheets(100/case)

1"

Roll Length960-360 yards60-360 yardsIf roll form:360 yards

CoreSize3"3"If roll form:6" cores

SlitTolerance±1/32"±1/32"If roll form:±1/32"

48"60-360 yards3"±1/32"

54"54"

1"1"

60-360 yards180 yards

3"3"

±1/32"±1/32

Note 9: Roll lengths vary by product slit width (the customer service department has more

detailed information, 1-800-328-1681).

Application Techniques

For maximum bond strength (during installation of the final part) the surface shouldbe thoroughly cleaned and dried. Typical cleaning solvents are heptane (for oilysurfaces) or isopropyl alcohol for plastics. Use reagent grade solvents since commonhousehold materials like rubbing alcohol frequently contain oils to minimize thedrying affect on skin. These oils can interfere with the performance of a pressure-sensitive adhesive. Consult solvent manufacturer’s MSDS for proper handling andstorage instructions. Also, use disposable wipes that do not contain oils to removethe cleaning solvents. This cleaning recommendation may not be compliant with therules of certain Air Quality Management Districts in California; consult applicablerules before use.

It is necessary to provide pressure during lamination (1.5-20 pli recommended) andduring final part installation (10-15 psi) to allow the adhesive to come into directcontact with the substrate. Using a hard edged plastic tool, which is the full width ofthe laminated part, helps to provide the necessary pressure at the point of lamination.Heat can increase bond strength when bonding to metal parts (generally this sameincrease is observed at room temperature over longer times, weeks). For plasticparts, the bond strength is not enhanced with the addition of heat.

The ideal adhesive application temperature range is 60°F (21°C) to 100°F (38°C).Application is not recommended if the surface temperature is below 50°F (10°C)because the adhesive becomes too firm to adhere readily. Once properly applied, atthe recommended application temperature, low temperature holding is generallysatisfactory (please refer to section VII of the Typical Physical Properties andPerformance Characteristics).

When bonding a thin, smooth, flexible material to a smooth surface, it is generallyacceptable to use 2 mils of adhesive. If a texture is visible on one or both surfaces,the 5 mil adhesive would be suggested. If both materials are rigid, it may benecessary to use a thicker adhesive to successfully bond the components. 3M?VHB?Acrylic Foam Tapes may be required (please refer to the data page for3M?VHB?Tapes, 70-0709-3830-6).

- 6 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MPApplication Equipment1)Wide web lamination

To apply adhesives in a wide web format, lamination equipment is required toensure acceptable quality. To learn more about working with pressure-sensitiveadhesives please refer to technical bulletin #70-0704-1430-8, LaminationTechniques for Converters of Laminating Adhesives.

2)To apply narrow strips of adhesive

Manual Dispensers - P-52, P-56

Define Length Dispensers - M-96

Semiautomatic Dispensers - S-625 w/attachment, T-646

For assistance in helping you determine the best dispenser for your application,contact your local 3M sales representative, or the toll free 3M sales assistancenumber at 1-800-362-3550.

Application Ideas?Long term bonding of graphic nameplates and overlays (“subsurface” printed

polycarbonate or polyester) to metal and high surface energy plastics in theaerospace, medical and industrial equipment, automotive, appliance and electronicmarkets.

?Bonding metal nameplates and rating plates in the aerospace, medical andindustrial equipment, automotive, appliance and electronic markets.

?Bonding graphic overlays for membrane switches and for bonding the completeswitch to the equipment surface.

- 7 -

3M?High Performance Adhesive TransferTapes with 3M?Adhesive 200MPFor AdditionalInformationTo request additional product information or to arrange for sales assistance, call toll free 1-800-362-3550

or visit www.3M.com/bonding. Address correspondence to: 3M Bonding Systems Division, 3M Center,Building 220-7E-01, St. Paul, MN 55144-1000. Our fax number is 651-733-9175. In Canada, phone: 1-800-364-3577. In Puerto Rico, phone: 1-809-750-3000. In Mexico, phone: 5-728-2180.

Certification/RecognitionTSCA: These products are defined as articles under the Toxic Substances Control Act and therefore, are

exempt from inventory listing requirements.

MSDS: These products are not subject to the MSDSrequirements of the Occupational Safety and HealthAdministration’s Hazard Communication Standard, 29 C.F.R. 1910.1200(b)(6)(v). When used underreasonable conditions or in accordance with the 3M directions for use, these products should not presenta health and safety hazard. However, use or processing of the products in a manner not in accordancewith the directions for use may affect their performance and present potential health and safety hazards.UL: Many of these products have been recognized by Underwriters Laboratories Inc. under Standard, UL969, Marking and Labeling Systems Materials Component. For more information on the UL Certification,please visit the 3M website at /converter.

Important Notice3M MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. User isresponsible for determining whether the 3M product is fit for a particular purpose and suitable for user’smethod of application. Please remember that many factors can affect the use and performance of a 3Mproduct in a particular application. The materials to be bonded with the product, the surface preparationof those materials, the product selected for use, the conditions in which the product is used, and the timeand environmental conditions in which the product is expected to perform are among the many factorsthat can affect the use and performance of a 3M product. Given the variety of factors that can affect theuse and performance of a 3M product, some of which are uniquely within the user’s knowledge andcontrol, it is essential that the user evaluate the 3M product to determine whether it is fit for a particularpurpose and suitable for the user’s method of application.Limitation of Remediesand LiabilityIf the 3M product is proved to be defective, THE EXCLUSIVE REMEDY, AT 3M’S OPTION, SHALL BE TO

REFUND THE PURCHASE PRICE OF OR TO REPAIR OR REPLACE THE DEFECTIVE 3M PRODUCT.3M shall not otherwise be liable for loss or damages, whether direct, indirect, special, incidental, orconsequential, regardless of the legal theory asserted, including, but not limited to, contract, negligence,warranty, or strict liability.

This Bonding Systems Division product was manufactured under a 3M quality system registered to ISO

9002 standards.

3

Bonding Systems Division

3M Center, Building 220-7E-01St. Paul, MN 55144-1000Recycled Paper40% pre-consumer

10% post-consumerPrinted in U.S.A.

?3M IPC 200170-0709-3858-7

- 8 -