1. 数控车

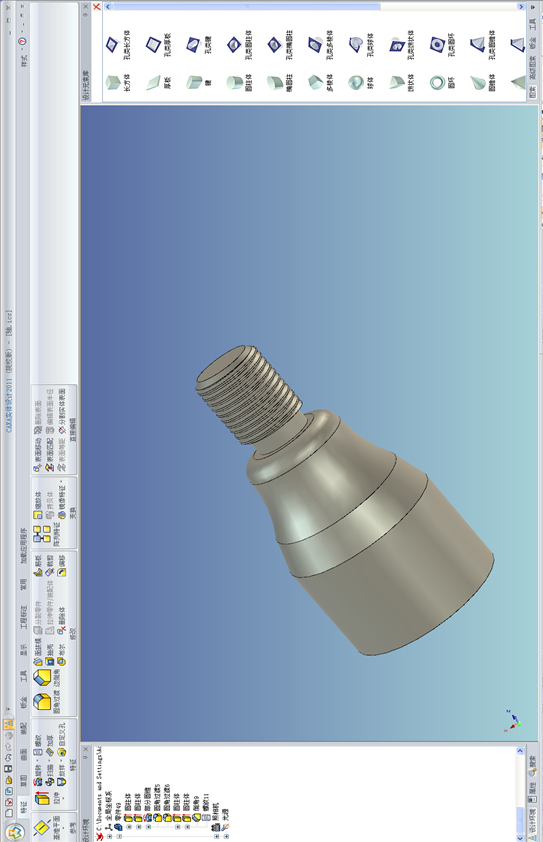

1.1 实体造型图

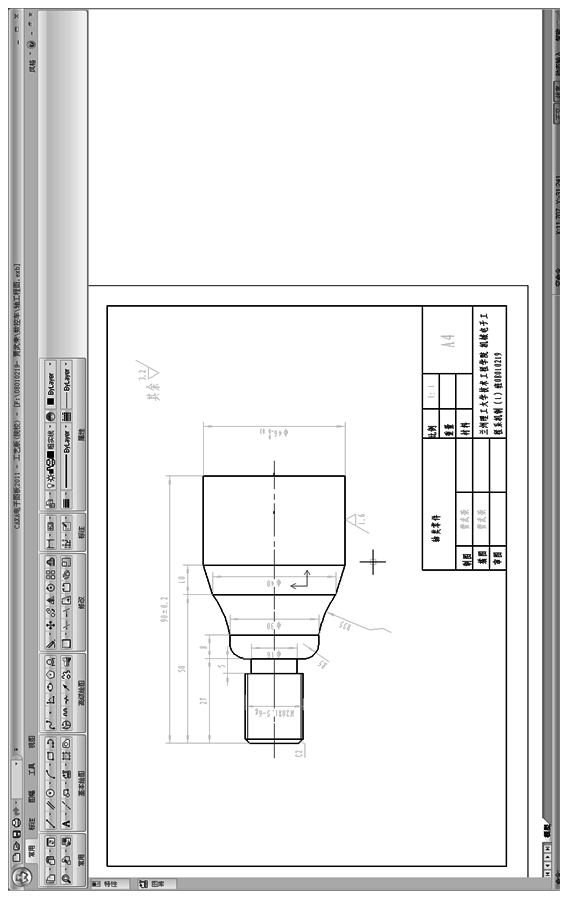

1.2 工程图

1.2 数控车仿真加工

1.4后置处理

O1234

(NC0001.CUT,01/09/12,10:00:48)

N10 G50 S10000

N12 G00 G97 S800 T0000

N14 M03

N16 M08

N18 G00 X-81.726 Z-95.747

N20 G00 Z-90.500

N22 G00 X-75.292

N24 G42

N26 G01 X-65.292 F5.000

N28 G01 Z-52.020 F0.300

N30 G01 X-75.292 F20.000

N32 G00 Z-90.500

N34 G01 X-62.292 F5.000

N36 G01 Z-52.020 F0.300

N38 G01 X-72.292 F20.000

N40 G00 Z-90.500

N42 G01 X-59.292 F5.000

N44 G01 Z-52.020 F0.300

N46 G01 X-69.292 F20.000

N48 G00 Z-90.500

N50 G01 X-56.292 F5.000

N52 G01 Z-52.020 F0.300

N54 G01 X-66.292 F20.000

N56 G00 Z-90.500

N58 G01 X-53.292 F5.000

N60 G01 Z-52.020 F0.300

N62 G01 X-63.292 F20.000

N64 G00 Z-90.500

N66 G01 X-50.292 F5.000

N68 G01 Z-52.020 F0.300

N70 G01 X-60.292 F20.000

N72 G00 Z-90.500

N74 G01 X-47.292 F5.000

N76 G01 Z-52.020 F0.300

N78 G01 X-57.292 F20.000

N80 G00 Z-90.000

N82 G01 X-47.000 F5.000

N84 G01 Z-52.520 F0.300

N86 G01 X-75.292 F20.000

N88 G00 X-81.726

N90 G40 G00 Z-95.747

N92 M09

N94 M30

%

O1234

(NC0002.CUT,01/09/12,10:01:57)

N10 G50 S10000

N12 G00 G97 S800 T0000

N14 M03

N16 M08

N18 G00 X-73.718 Z-96.076

N20 G00 Z-90.000

N22 G00 X-58.214

N24 G42

N26 G01 X-46.800 F5.000

N28 G01 Z-52.520 F0.300

N30 G01 X-48.214 Z-53.228 F20.000

N32 G01 X-58.214

N34 G00 Z-90.000

N36 G01 X-46.600 F5.000

N38 G01 Z-52.520 F0.300

N40 G01 X-48.014 Z-53.228 F20.000

N42 G01 X-58.014

N44 G00 Z-90.000

N46 G01 X-46.400 F5.000

N48 G01 Z-52.520 F0.300

N50 G01 X-47.814 Z-53.228 F20.000

N52 G01 X-57.814

N54 G00 Z-90.000

N56 G01 X-46.200 F5.000

N58 G01 Z-52.520 F0.300

N60 G01 X-47.614 Z-53.228 F20.000

N62 G01 X-57.614

N64 G00 Z-90.000

N66 G01 X-46.000 F5.000

N68 G01 Z-52.520 F0.300

N70 G01 X-47.414 Z-53.228 F20.000

N72 G01 X-58.214

N74 G00 X-73.718

N76 G40 G00 Z-96.076

N78 M09

N80 M30

%

O1234

(NC0003.CUT,01/09/12,10:03:28)

N10 G50 S10000

N12 G00 G97 S800 T0000

N14 M03

N16 M08

N18 G00 X94.265 Z13.778

N20 G00 Z0.500

N22 G00 X86.465

N24 G42

N26 G01 X76.465 F5.000

N28 G01 Z-60.500 F0.300

N30 G01 X86.465 F20.000

N32 G00 Z0.500

N34 G01 X73.465 F5.000

N36 G01 Z-60.500 F0.300

N38 G01 X83.465 F20.000

N40 G00 Z0.500

N42 G01 X70.465 F5.000

N44 G01 Z-60.500 F0.300

N46 G01 X80.465 F20.000

N48 G00 Z0.500

N50 G01 X67.465 F5.000

N52 G01 Z-60.500 F0.300

N54 G01 X77.465 F20.000

N56 G00 Z0.500

N58 G01 X64.465 F5.000

N60 G01 Z-60.500 F0.300

N62 G01 X74.465 F20.000

N64 G00 Z0.500

N66 G01 X61.465 F5.000

N68 G01 Z-60.500 F0.300

N40 G18 G03 X40.766 Z-49.885 R0.400

N42 G01 X46.766 Z-59.885

N44 G01 X47.714 Z-59.005 F20.000

N46 G01 X57.714

N48 G00 Z0.212

N50 G01 X16.424 F5.000

N52 G01 X20.424 Z-1.788 F0.300

N54 G18 G03 X20.600 Z-2.000 R0.300

N56 G01 Z-26.708

N58 G18 G03 X30.600 Z-32.000 R5.300

N60 G01 Z-34.986

N62 G18 G02X40.512 Z-49.843 R34.700

N64 G18 G03 X40.575 Z-49.914 R0.300

N74 G01 X16.283 F5.000

N76 G01 X20.283 Z-1.859 F0.300

N78 G18 G03 X20.400 Z-2.000 R0.200

N80 G01 Z-26.804

…………………………………………………………………….

N94 G01 X57.331

N96 G00 Z0.071

N98 G01 X16.141 F5.000

N100 G01 X20.141 Z-1.929 F0.300

N102 G18 G03 X20.200 Z-2.000 R0.100

N104 G01 Z-26.901

N106 G18 G03 X30.200 Z-32.000 R5.100

N108 G01 Z-34.995

N110 G18 G02X40.171 Z-49.948 R34.900

N112 G18 G03 X40.192 Z-49.971 R0.100

N114 G01 X46.192 Z-59.971

N116 G01 X47.140 Z-59.091 F20.000

N118 G01 X57.140

N120 G00 Z0.000

N122 G01 X16.000 F5.000

N124 G01 X20.000 Z-2.000 F0.300

N126 G01 Z-27.000

N128 G18 G03 X30.000 Z-32.000 R5.000

N130 G01 Z-35.000

N132 G18 G02X40.000 Z-50.000 R35.000

N134 G01 X46.000 Z-60.000

N136 G01 X46.948 Z-59.120 F20.000

N138 G01 X57.714

N140 G00 X80.230

N142 G40 G00 Z6.228

N144 M09

N146 M30

%%

O1234

(NC0006.CUT,01/09/12,10:06:23)

N10 G50 S10000

N12 G00 G97 S500 T0000

N14 M03

N16 M08

N18 G00 X29.143 Z-22.020

N20 G00 X44.000 Z-25.300

N22 G42

N24 G01 X32.000 F5.000

N26 G01 X17.000 F0.300

N28 G04X0.500

N30 G01 X44.000 F20.000

N32 G00 Z-26.500

N34 G01 X32.000 F5.000

N36 G01 X17.000 F0.300

N38 G04X0.500

N40 G01 X44.000 F20.000

N42 G01 X32.000 F5.000

N44 G01 X20.000

N46 G01 X17.000 F0.300

N48 G04X0.500

N50 G01 X32.000 F20.000

N52 G00 Z-25.300

N54 G01 X20.000 F5.000

N56 G01 X17.000 F0.300

N58 G04X0.500

N60 G01 Z-26.500

N62 G04X0.500

N64 G01 X32.000 F20.000

N66 G00 Z-25.200

N68 G01 X20.000 F5.000

N70 G01 X16.800 F0.300

N72 G01 Z-26.600

N74 G01 X20.000

N76 G01 X32.000 F20.000

N78 G00 Z-25.100

N80 G01 X20.000 F5.000

N82 G01 X16.600 F0.300

N84 G01 Z-26.700

N86 G01 X20.000

N88 G01 X32.000 F20.000

N90 G00 Z-25.000

N92 G01 X20.000 F5.000

N94 G01 X16.400 F0.300

N96 G01 Z-26.800

N98 G01 X20.000

N100 G01 X32.000 F20.000

N102 G00 Z-24.900

N104 G01 X20.000 F5.000

N106 G01 X16.200 F0.300

N108 G01 Z-26.900

N110 G01 X20.000

N112 G01 X32.000 F20.000

N114 G00 Z-24.800

N116 G01 X20.000 F5.000

N118 G01 X16.000 F0.300

N120 G01 Z-27.000

N122 G01 X20.000

N124 G01 X32.000 F20.000

N126 G40 G00 X29.143 Z-22.020

N128 M09

N130 M30

%

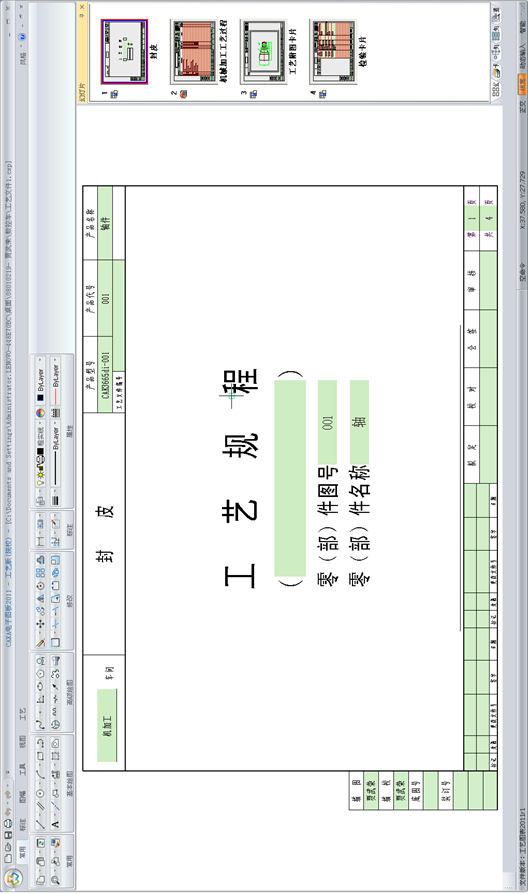

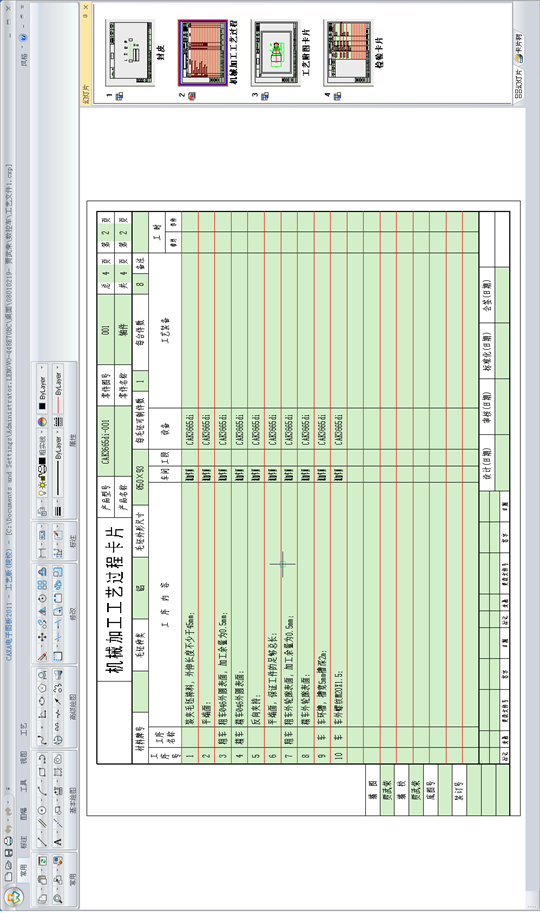

1.5工艺卡片

1.5工艺卡片

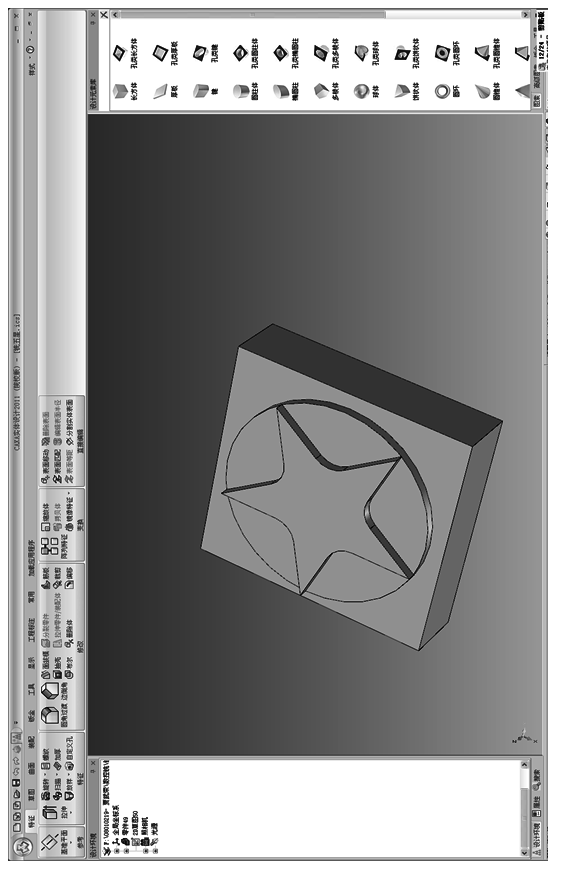

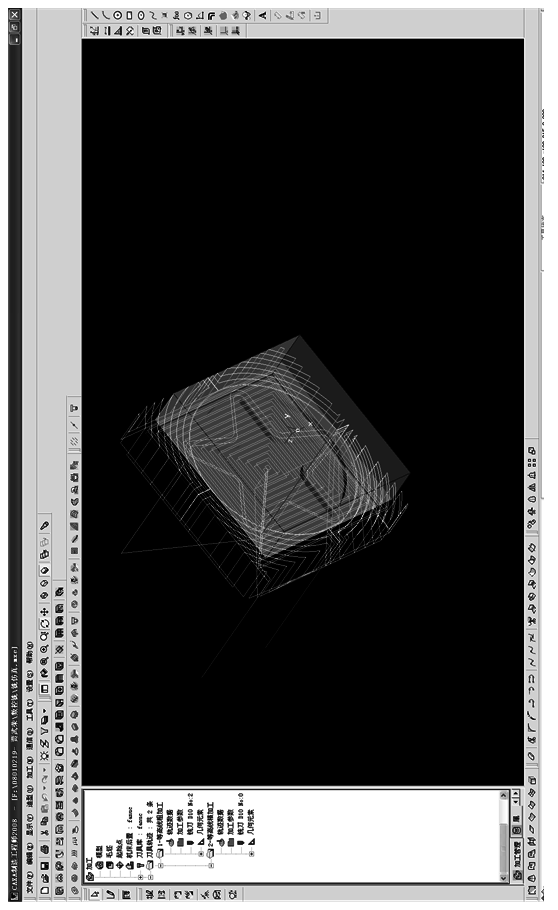

2. 铣加工中心

2.1 实体造型图

2.3仿真加工

2.4 NC代码

粗208,2011.12.26,14:14:7.98)

N10G90G54G00Z100.000

N12S3000M03

N14X33.591Y47.500Z100.000

N16Z33.000

N18G01Z23.000F100

N20G02X34.054Y46.263I-32.239J-12.796F800

N22G02X34.498Y44.907I-28.285J-9.997

N24G02X34.761Y44.030I-603.925J-181.656

N26G01X36.424Y43.908

N28G02X38.287Y43.712I-2.194J-29.920

N30G02X47.410Y41.158I-4.676J-34.267

N32G01Z33.000F100

N34G00Z100.000

N36X-46.458Y43.813

N38Z33.000

N40G01Z23.000F100

N42G02X-36.227Y46.518I13.872J-31.774F800

N44G02X-32.087Y46.667I3.150J-29.834

N46G01X-31.216Y46.638

N48G02X-30.888Y47.500I32.568J-11.934

N50G01Z33.000F100

N52G00Z100.000

N54X28.138

N56Z33.000

N58G01Z23.000F100

N60G02X29.340Y44.597I-26.786J-12.796F800

N62G02X29.710Y43.467I-23.571J-8.331

N64G02X30.983Y39.179I-599.137J-180.216

N66G03X33.014Y39.119I26.736J874.308F1000

N68G02X34.136Y39.062I-0.706J-24.990

N70G01X36.059Y38.921

N72G02X37.611Y38.758I-1.828J-24.933

N74G02X47.500Y35.567I-4.000J-29.313

N76G01Z33.000F100

N78G00Z100.000

N80Y-16.865

N82Z33.000

N84G01Z23.000F100

N86X46.813Y-17.326F800

N88G03X47.500Y-19.782I4791.644J1338.129

N90G01Z33.000F100

N92G00Z100.000

N94Y-38.024

N96Z33.000

N98G01Z23.000F100

N100G02X42.819Y-46.950I-28.215J9.107F800

N102G01Z33.000F100

N104G00Z100.000

N106X-44.745Y-45.808

N108Z33.000

N110G01Z23.000F100

N112G02X-47.124Y-42.346I23.211J18.495F800

N114G01Z33.000F100

N116G00Z100.000

N118X-47.500Y37.689

N120Z33.000

N122G01Z23.000F100

N124G02X-35.702Y41.545I14.913J-25.649F800

N126G02X-32.252Y41.670I2.625J-24.862

N128G02X-27.692Y41.517I-165.842J-5022.254

N130G01X-27.180Y42.901

N132G02X-25.435Y47.500I28.531J-8.197

N134G01Z33.000F100

N136G00Z100.000

N138X22.462

N140Z33.000

N142G01Z23.000F100

N144G02X24.626Y42.931I-21.110J-12.796F800

N146G02X24.922Y42.027I-18.857J-6.665

N148G02X27.191Y34.300I-594.349J-178.776

N150G03X32.873Y34.121I30.527J879.187F1000

N152G02X33.770Y34.075I-0.565J-19.992

N154G01X35.693Y33.934

N156G02X36.935Y33.804I-1.462J-19.946

N158G02X47.500Y29.731I-3.324J-24.358

N160G01Z33.000F100

N162G00Z100.000

N164Y-10.839

N166Z33.000

N168G01Z23.000F100

N170G02X47.381Y-10.920I-11.285J16.512F800

N172G02X41.027Y-15.189I-2802.665J4164.788

N174G03X42.773Y-21.446I4797.430J1335.992

N176G02X35.478Y-47.5--------------------------------------------------------

N5760X-12.100Y-12.100

N5762X12.100

N5764Y10.590

N5766Y11.182Z26.068

N5768Y11.768Z25.972

N5770X11.341Y12.100

N5772X10.236Z26.068

N5774X-8.389Z26.100

N5776X-10.614Z26.077

N5778X-12.100Y11.373Z26.100

N5780Y-12.100

N5782X-11.100Y-11.100

N5784X11.100

N5786Y10.800

N5788X10.800Y11.100

N5790X-11.100

N5792Y-11.100

N5794X-10.100Y-10.100

N5796X10.100

N5798Y10.100

N5800X-10.100

N5802Y-10.100

N5804X-9.100Y-9.100

N5806X9.100

N5808Y9.100

N5810X-9.100

N5812Y-9.100

N5814X-8.100Y-8.100

N5816X8.100

N5818Y8.100

N5820X-8.100

N5822Y-8.100

N5824X-7.100Y-7.100

N5826X7.100

N5828Y7.100

N5830X-7.100

N5832Y-7.100

N5834X-6.100Y-6.100

N5836X6.100

N5838Y6.100

N5840X-6.100

N5842Y-6.100

N5844X-5.100Y-5.100

N5846X5.100

N5848Y5.100

N5850X-5.100

N5852Y-5.100

N5854X-4.100Y-4.100

N5856X4.100

N5858Y4.100

N5860X-4.100

N5862Y-4.100

N5864X-3.100Y-3.100

N5866X3.100

N5868Y3.100

N5870X-3.100

N5872Y-3.100

N5874X-2.100Y-2.100

N5876X2.100

N5878Y2.100

N5880X-2.100

N5882Y-2.100

N5884X-1.100Y-1.100

N5886X1.100

N5888Y1.100

N5890X-1.100

N5892Y-1.100

N5894X-0.100Y-0.100

N5896X-1.904Y-1.902

N5898X-18.246Y-18.218

N5900X-19.210Y-19.181Z26.068

N5902X-20.162Y-20.131Z25.972

N5904X-21.090Y-21.058Z25.814

N5906X-21.983Y-21.950Z25.595

N5908X-22.830Y-22.795Z25.318

N5910X-23.619Y-23.583Z24.987

N5912X-24.359Y-24.322Z24.594

N5914X-25.450Y-25.411Z23.802

N5916X-25.624Y-25.585Z23.630

N5918X-26.255Y-26.215Z22.804

N5920X-26.570Y-26.529Z22.417

N5922X-26.920Y-26.879Z22.091

N5924X-28.374Y-28.331Z17.100

N5926X-39.792Y-40.100Z17.094

N5928Z27.094F100

N5930G00Z100.000

N5932M05

N5934M30

2.5工艺卡片

3. 线切割

3.1自行设计零件图

3.3NC代码

****************************************

CAXAWEDM -Version 2.0 , Name : 000.3B

Conner R= 0.00000 , Offset F= 1.00000 ,Length= 815.543 mm

****************************************

Start Point = 24.93872 , 97.09512 ; X , Y

N 1: B 25 B 3447 B 3447 GY L1 ; 24.964 , 100.542

N 2: B 27400 B 199 B 27400 GX L2 ; -2.436 , 100.741

N 3: B 24292 B 32285 B 32285 GY L3 ; -26.728 , 68.456

N 4: B 22281 B 12469 B 22281 GX L4 ; -4.447 , 55.987

N 5: B 20635 B 27527 B 27527 GY L1 ; 16.188 , 83.514

N 6: B 0 B 201995 B 201995 GY L4 ; 16.188 , -118.481

N 7: B 38255 B 348 B 38255 GX L3 ; -22.067 , -118.829

N 8: B 0 B 21821 B 21821 GY L4 ; -22.067 , -140.650

N 9: B 113302 B 354 B 113302 GX L4 ; 91.235 , -141.004

N 10: B 377 B 26019 B 26019 GY L2 ; 90.858 , -114.985

N 11: B 44151 B 347 B 44151 GX L3 ; 46.707 , -115.332

N 12: B 348 B 215714 B 215714 GY L1 ; 47.055 , 100.382

N 13: B 22091 B 160 B 22091 GX L2 ; 24.964 , 100.542

N 14: B 7 B 999 B 999 GY L3 ; 24.957 , 99.543

N 15: DD