项目可行性分析研究

——工业经济学课程设计报告

课程设计题目:某新建电子配件厂项目

指导教师:

班级:

姓名:

学号:

班内序号:

2014.5.20

目录

(一)课题概述……………………………………………2

1.项目名称……………………………………………………………………………2

2.基础数据……………………………………………………………………………2

(二)财务评价……………………………………………4

1.财务净现值…………………………………………………………………………4

2.内部收益率…………………………………………………………………………4

3.静态和动态投资回收期……………………………………………………………4

4.投资利润率…………………………………………………………………………5

5.资本金净利润率……………………………………………………………………5

6.借款偿还期等指标…………………………………………………………………5

(三)风险分析……………………………………………5

1.盈亏平衡分析………………………………………………………………………5

2.敏感性分析…………………………………………………………………………6

3.概率分析……………………………………………………………………………7

4.风险决策分析………………………………………………………………………9

(四)项目评价与结论…………………………………10

附表………………………………………………………11

实验总结与心得…………………………………………20

(一)课题概述

1.项目名称

某新建电子配件厂

2.基础数据

1)生产规模

该项目建成后拟生产目前市场上所需的计算机配件,设计生产规模为年产100万件。

2)实施进度

该项目拟二年建成,第三年投产,当年生产负荷达到设计生产能力的70%,第四年达到90%,第五年达到100%。生产期按12年计算,计算期为14年。

70%的营业收入=80*100*70%=5600万元

90%的营业收入=80*100*90%=7200万元

100%的营业收入=80*100*100%=8000万元

3)建设投资估算

经估算,该项目建设投资总额为5700万元(不含建设期利息),其中:预计形成固定资产4910万元,无形资产490万元,其他资产300万元。

4)流动资金估算

该项目的流动资金估算总额为1150万元。

5)投资使用计划与资金来源

建设投资分年使用计划按第一年投入2000万元,第二年投入3700万元;流动资金从投产第一年开始按生产负荷进行安排。

该项目的资本金为2110万元,其中用于建设投资1700万元,其余用于流动资金。建设投资缺口部分由中国建设银行贷款解决,年利率为6%;流动资金缺口部分由中国工商银行贷款解决,年利率为4%。

6)销售收入和销售税金及附加估算

根据市场分析,预计产品的市场售价(不含税)为80元/件。本产品采用价外计税,增值税税率为17%,城市维护建设税和教育费附加的税率分别为7%和3%。

增值税=(营业收入-材料费)*0.17

城市维护建设税和教育费附加=增值税*(7%+3%)

7)产品总成本估算

(1)该项目正常年份的外购原材料、燃料动力费(不含税)为5000万元;

(2)据测算,该项目的年工资及福利费估算为150万元;

(3)固定资产折旧费按平均年限法计算,折旧年限为12年,残值率为5%;

(4)无形资产按10年摊销,其他资产按5年摊销;

(5)修理费按折旧费的40%计取;

(6)年其他费用为320万元;

(7)项目在生产经营期间的应计利息全部计入财务费用。建设投资借款在生产经营期按全年计息;流动资金当年借款按全年计息。

8)利润测算

(1)所得税率按33%考虑;

(2)盈余公积金按税后利润的10%计取。

9)评价参数

设基准收益率为15%;基准投资利润率和资本金净利润率分别为20%和30%;基准的静态投资回收期和动态投资回收期分别为7年和10年;中国建设银行对这类项目所要求的借款偿还期不能超过6年。

(二)财务评价

附财务分析的八张报表。

1.财务净现值

财务净现值是指把项目计算期内各年的财务净现金流量,按照一个给定的标准折现率(基准收益率)折算到建设期初(项目计算期第一年年初)的现值之和。财务净现值是考察项目在其计算期内盈利能力的主要动态评价指标。

根据现金流量表7和表8

自有资金条件下,该项目的在14年后累计净现值为3559.91 万元。

全投资条件下,该项目的在14年后累计净现值为3932.45万元。

2.内部收益率

即为投资方案净现值为0的折现率。自有资金条件下,IRR=28.09%

高于基准收益率15%。

3.静态和动态投资回收期

静态投资回收期是指在不考虑时间价值的情况下,收回全部原始投资额所需要的时间,即投资项目在经营期间内预计净现金流量的累加数恰巧抵偿其在建设期内预计现金流出量所需要的时间,也就是使投资项目累计净现金流量恰巧等于零所对应的期间。由现金流量表7第5栏累计净现金流量可知

全投资静态回收期Tp=5+513.95/(513.95+1602.76)=5.24年小于基准静态回收期7年。

动态投资回收期是指在考虑货币时间价值的条件下,以投资项目净现金流量的现值抵偿原始投资现值所需要的全部时间。即:动态投资回收期是项目从投资开始起,到累计折现现金流量等于0时所需的时间。由现金流量表7第8栏累计净现金流现值可知

动态回收期Tp*=5+291.61/(291.61+811.96)=5.26年,小于基准动态回收期10年。

4.投资利润率

投资利润率是指项目在正常生产年份内所获得的年利润总额或年平均利润总额与项目全部投资的比率。由全投资现金流量表及损益表可知

ROI=年利润或年均利润/投资总额×100%=1523.61/5700*100%=26.73%

大于基准投资利润率20%

5.资本金净利润率

股本回报率是指税后净利润对股本投资额的比值。

由全投资现金流量表及损益表可知

ROE=1523.61/2110*100%=72.21%

大于资本金净利润率30%

6.借款偿还期

项目投产后以可用作还款的利润、折旧、摊销及其他收益偿还建设投资借款本金(含未付建设期利息)所需要的时间。

借款偿还期=(借款偿还开始出现盈余年份-1)+(盈余当年应偿还借款额/盈余当年可用于还款的余额)=6-1+(800+29.6+48)/2871.96=5.31年,小于所要求的借款偿还期6年。

(三)风险分析

1.盈亏平衡分析

通过计算产量、生产能力利用率、单位产品售价的盈亏平衡点进行分析。

根据成本费用表,每万件产品的直接材料费为50万,其他固定费用为759.58万元。

1)产量

盈亏平衡产量Q*=Cf/(P-Cv)=759.58/(81.36-50)=24.22万件

即产量大于24.22万件时,项目盈利,小于24.22万件时,项目亏损,等于24.22万件时,项目不盈不亏。

2)生产能力利用率

盈亏平衡生产能力利用率 E*=Q*/Q*100%=Cf/[(P-Cv)Qc]*100%=24.22/100=24.22%

即生产能力利用率大于24.22%时,项目盈利,小于24.22%时,项目亏损,等于24.22%时,项目不盈不亏。

3)单位产品销售价格

盈亏平衡销售价格 P*=Cv=Cf/Qc=50+759.58/100=57.60元

即销售价格大于57.60元时,项目盈利,小于57.60元时,项目亏损,等于57.60元时,项目不盈不亏。

通过计算盈亏平衡点,结合市场预测,可以对投资方案的发生亏损的可能性做大致判断。如果未来产品的销售价格及生产成本与预期相同,项目不发生亏损的条件是年产量不低于24.22万件,即生产能力利用率不低于24.22%;如果按设计能力生产并能全部销售,生产成本与预期值相同,项目不发生亏损的条件是产品价格不低于57.60元/件。

2.敏感性分析

分别就建设投资、经营成本和销售收入变动(假设变动范围为±10%,变动幅度为5%)时对项目内部收益率的影响进行单因素敏感性分析。要求找出因素变动的临界值、绘制敏感性分析图等。

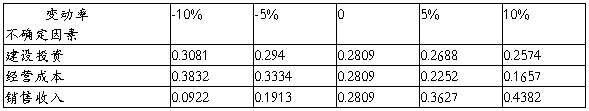

根据自有投资现金流量表,分别将建设投资经营成本和销售收入变动-10%、-5%、5%、10%后得到项目内部收益率变化情况如下表:

由敏感性分析图可知,对于本投资方案,经营成本和销售收入都是影响内部收益率的敏感因素。经营成本和销售收入的变动都会使内部收益率产生大幅度的变化,销售收入的影响最大。由插值法可以得到销售收入变动率的临界值为-5%-5*(0.1913-0.15)/(0.1913-0.0922)=-7.08%;同理可以计算出经营成本变动率的临界值为11.54%。因此,实施方案过程中严格控制经营成本并努力提高销售收入是提高经济效益的主要途径。而建设投资敏感度较差,在变动50%以上后才会到达临界值,对决策结论影响较小,不必予以过多关注。

3.概率分析

假设建设投资、经营成本和销售收入可能发生的变动及相应的概率(主观概率)如下表。

将三个影响因素组合可得到27种可能方案,其净现值按照从小到大排序如下表所示:

可见,所有可能情况的净现值均大于零,故项目财务净现值的期望值大于零的概率是100%。净现值期望为每种情况下净现值的加权平均,为3724.02万元。

4.风险决策分析

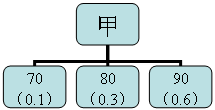

现有甲乙两家原材料供应商,甲原材料质量价格均高于乙,两者提供的原材料以不同价格销售概率如下:

六种情况的累积净现值依次为:-33.16、2373.23、4779.63、2340.20、4746.59、7152.99

E甲=-33.16*0.1+2373.23*0.3+4779.63*0.6=3576.43万元

E乙=2340.20*0.3+4746.59*0.5+7152.99*0.2=4505.95万元

E(NPV甲)>E(NPV乙)

故在生产销售条件与预期相同的条件下,选择乙供应商更为有利。

(四)项目评价与结论

1.偿债能力

由资金来源与运用表可以看出,由项目筹措的资金和项目的净收益足可支付各项支出,不需借短期借款皆可保证资金收支相抵有余。在该表中,各年累计盈余资金均大于零,可满足项目运行要求。

从借贷还本付息表中可以看出,项目可筹集足够的资金按与银行商定的方式偿还贷款。从资产负债表的资产负债率、流动比率、速动比率三项指标来看,流动比率和速动比率较高;同时,资产负债率也较高,但由于该项目整体盈利能力强,风险相对不大。在项目达到设计能力后,三项指标更为好转。

静态回收期和动态回收期都远小于基准值,借款偿还期也小于限定最大值。

从整体看,该项目的偿债能力较强。

2.盈利能力

内部收益率远大于基准折现率,作为评价的重要指标,较高的内部收益率保证了项目的盈利能力。投资利润率超过基准值,资本金利润率比较高,说明了此项目借款数额比较大,但资本的盈利能力很强。

项目的各项盈利指标都很可观,盈利能力好。

3.抗风险能力

从盈亏平衡上看,该项目抗风险能力非常强。但是根据敏感性分析,项目实施时要格外关注经营成本和销售收入的变动。建设投资对收益影响不大,可灵活调节。当经营成本、销售收入和建设投资变动均在10%以内时,可保证项目不亏损,项目累计净现值的期望约为项目资本金的1.5倍。

从总体看,该项目的投资效果较好。

第二篇:国际工程管理作业(资格预审)

PRE-QUALIFICATION

REQUEST FOR PROPOSAL

FOR THE

SHAFT DEEPENING AND

RELATED

DEVELOPMENT/CONSTR

UCTION

RFP FOR CONTRACT NO.

BEIJING WANGJING

CHINA

FOUNDATION PIT P.K. 0086, 100010 BEIJING S&E ENG. B.J., CHINA

? TABLE OF CONTENTS ? SECTION

? 1.0 PROJECT INFORMATION ? 2.0 INSTRUCTIONS FOR SUBMITTING PREQUALI- FICATION PROPOSALS

? 3.0 CORPORATE INFORMATION ? 4.0 FINANCIAL INFORMATION ? 5.0 RELATED PIT PROJECT CONTRACTING EXPERIENCE ? 6.0 INTERNATIONAL PIT PROJECT CONTRACTING EXPERIENCE

? 7.0 HEALTH AND SAFETY PROGRAM & RECORD

? 8.0 KEY MANAGEMENT AND FIELD SUPERVISION PERSONNEL

1.0 PROJECT INFORMATION ? 1.1 LOCATION

? Cayeli Mine (Cayeli) is located in the Black Sea region of Northeast Turkey (refer to maps below). The mine is approximately 28 km east of Rize and the nearest town, Cayeli, is 8 km north of the mine. Access to the Site from Cayeli is by the Cayeli/Kaptanpasa road only.

? The project area can be reached by road from Ankara or via Samsun, Trabzon and Rize. The road distance from Ankara is approximately 900 km. The mine site can also be reached by Turkish Air to Trabzon (via Ankara or Instanbul) and then driving

approximately 100 km to Cayeli. ? 1.2 THE OWNER

? Cayeli Bakir Isletmeleri A.S. was created under the laws of Turkey, as provided for in decree number 83/6533

of the Council of Ministers dated April 26, 1983. The purpose of the

? company is to develop copper, zinc and certain other mineral resources in the north-eastern part of Turkey. ? 1.3 THE PROJECT

? The mine is operated by Cayeli Bakir Isletmeleri AS (CBI) and produces copper and zinc concentrates by processing massive sulphide ore. Present ore production is 1.0 million tonne. As part of Cayeli’s ongoing long term production planning, ore production will be increased to 1.3 million tonnes.

? Cayeli plans to deepen their existing ore hoisting facility. The Work for the deepening project involves: ? The scope of work is outlined as follows:

? 1、 Engineering, design, fabricate, transport and set-up of appropriate

shaft sinking plant. The existing shaft service hoist and cage compartment of the shaft will be made available for use by the Contractor.

? 2、 Pre-sinking preparation of the facility as required. The Owner may expedite portions of this work with independent workers – decision prior to award.

? 3、Perform such works in the shaft in order to establish the sinking face while allowing continued mine production from the existing ore handling facilities. This may/will include excavation of the spill raise, installation of the shaft

sinking/deflector bulkhead below the existing 900 Level loading pocket, shaft bottom cleanout, temporary removal of shaft steel sets,

modifications to the shaft headframe

structure to allow surface dumping of waste rock, etc.

? 4、 Deepening the production shaft (surface elevation nominal 1109 metres) from the current elevation (±835 metres elevation) to 540 Elevation (nominal 295 metres of sinking). Concurrently, install pattern ground support as defined in the specifications, and install a 25 MPA monolithic concrete lining to 5.5 metres final inside diameter. Install shaft steel sets, services and

? electrics in accordance with project construction and final design requirements. At shaft bottom, excavate a “stub” station

approximately 10 metres long (for future breakthrough of shaft bottom ramp).

? 5.0 At the 570 Level, slash and line, in accordance with specifications, for a

twin flask (two compartments) loading pocket. Install and commission loading pocket.

? 6.0 At the 570 Level, excavate and support the main shaft station (nominal 2,300 cu m) in accordance with the final design and specifications. ? 7.0 Conduct shaft changeover as required to utilize the shaft cage and skips to the new elevations.

? 8.0 Transport equipment underground via shaft and complete the mine development program as identified. One purpose of the program is to complete the slimes/spill

handling/pumping system at/near 570 Level, connecting to the existing Geho dewatering sump/pump at 900 Level. ? 9.0 The development program will also complete the lower level ore handling system excavations. The system includes an extended length loadout

conveyor from the shaft loading pocket, associated ore pass raises (3) complete with chain controls, and vibratory feeders.

? 10.0 All excavations will be completed with final ground support (generally rebar bolts, cable bolts, and shotcrete) as specified.

? 11.0 Upon completion of the work, the Contractor shall remove, except as directed by the Owner representative, all temporary plant, buildings, surplus materials, equipment, tools, rubbish and debris. The Contractor shall leave the work site previously under his control and responsibility in a neat, clean and safe condition.

插图1

插图2

? 2.0 INSTRUCTIONS FOR SUBMITTING

PRE-QUALIFICATION

PROPOSALS

? 2.1 GENERAL

? Pre- Qualification Proposals (Proposals) for the work specified in this

documents must be submitted in accordance with the following instructions.

? 2.2 THE OWNER’S

REPRESENTATIVE

? For the purpose of liaison between the Owner for the pre-qualification process and the Contractor, the Owner’s representative will be:

? Mr. John Wright Technical Manager

? Cayeli Bakir Isletmeleri A.S. P.K. 42,

? 53200 Cayeli, Rize, Turkey

? Telephone No: (90) 464 544 64 30 Extension 227

? Facsimile No: (90) 464 544 62 84)

? Email:

? 2.3 SUBMISSION OF PROPOSAL ? Proposals must be sealed, complete and self-contained, regardless of pre-qualification documents. The original and Two (2) copies of the Pre-qualification Proposals shall be submitted by courier to the address specified above and labeled as follows:.

? PRE-QUALIFICATION

PROPOSAL

? RFP for Contract No. CAY 262 ? CAYELI MINE

? SHAFT DEEPENING & RELATED DEVELOPMENT/

CONSTRUCTION

? Sealed Proposals must be received on or before 30 January, 2003 at 12:00 hours local Turkish time (the “due date”). Note that faxed and/or e-mailed Proposals will be accepted but must be accompanied by a faxed copy of the appropriate signed courier receipt as proof of compliance that the appropriate original and copied documents are being delivered.

? Proposals will not be opened in public. The Contractor is to note that the Owner has the right to reject all or any proposals without explanation. ? 2.3 SCOPE OF WORK

? A general description of the Scope of Work has been provided in Section 1.3. ? 2.4 SCHEDULE OF WORK

? The following tentative schedule is for the Contractor’s information. ?

? Issuing Tender Documents - early February, 2003

? Closing of Tenders - late March, 2003 ? Expected Award of Contract - mid-April, 2003

? Completion of work - June. 2005 ? 2.5 COMMUNICATIONS ? All communications, written and spoken, between both parties in connection with this Proposal and Contract will be in the English

language and shall reference the RFQ or Contract Number as applicable. ? 2.6 CONTRACTOR’S

REPRESENTATIVE AND

SIGNATURES

? The signature(s) on behalf of the

Contractor must be in the handwriting of officers authorized to sign contracts for that party.

? The Contractor must give the full legal name under seal, the business address

of their company and consortium, and identify persons competent and

authorized to discuss the details of the Proposal.

? 2.7 PROPOSAL CLARIFICATION ? No oral interpretations shall be

effective to modify the provision of the Pre-Qualification Proposal Documents. Every request for

? interpretations shall be made in writing by letter, or facsimile, to the Owner. ? 3.0 CORPORATE INFORMATION ? The Contractor must submit the following corporate information:

? Corporate back ground and organization.

? Total current contracted workload. ? Number of home office and site personnel.

? 4.0 FINANCIAL INFORMATION ? 4.1 The Contractor must submit the following corporate

information:· Financial Report.

? Total estimated revenue for the next three (3) years (total corporation and mine contracting division (if

applicable)) Bonding

Limits· Certificates of insurance. ? 4.2 The Contractor acknowledges that by his signature hereunder, he consents to the Owner obtaining a credit report on the Contractor. Two bank references are to be supplied。

? 5.0 RELATED MINE CONTRACTING EXPERIENCE ? The Proposal must include details of the Contractor’s total shaft sinking and underground development and construction experience in undertaking projects of a similar magnitude and similar ground conditions to that of the Work. A list of relevant projects completed in the past five (5) years

shall be presented with the proposal. The list shall incorporate:

? · Descriptions of the Projects including location and key statistics (i.e. shaft diameter, shaft depth , linear meters of development etc)

? · Short description of manpower, equipment, and methods used in each project.

? 6.0 INTERNATIONAL MINE CONTRACTING EXPERIENCE ? The Proposal must also include details of the Contractor’s international (ie outside of the home country) shaft sinking and underground development and construction experience in undertaking projects of a similar magnitude and similar ground

? conditions to that of the Work. A list of relevant projects completed in the past five (5) years shall be presented

with the proposal. The list shall incorporate:

? · Descriptions of the Projects including location and key statistics (i.e. shaft diameter, shaft depth , linear meters of development etc)

? · Short description of manpower, equipment, and methods used in each project.

? · Nominal value in US Dollars ? · Overall schedule achieved

? · Description of major successes or failures for each project

? · Project safety records (including manhours worked, number of first aid incidents, number of medical aid incidents, number of lost-time accidents, number of fatal accidents (and short description of accident) for each project listed).

? · Project contact references including name, title, address, telephone number,

telefax number and email address (if available)

? 7.0 HEALTH AND SAFETY PROGRAM & RECORD

? The Contractor shall supply a copy of his standard safety program with the Proposal as well as a summary of the company’s accident history over the past five (5) years. If the company is involved in several distinct areas of work, the relevant statistics for the division responsible for shaft sinking and mine development are to be used.

? Safety Statistics

? 1998 1999 2000 2001 2002 ? A - Hours Worked

? B - Fatal Accidents

? C - Total Accidents

? D - Accidents with Lost Time

? E - Lost Days

? F - Lost Time Frequency

? G – Severity

? H – Compensation Costs

? Contractor’s Safety Program: ? 8.0 KEY MANAGEMENT AND FIELD SUPERVISION PERSONNEL

? The Contractor shall submit an organization chart for the Work which identifies key personnel and

be the submitted responsibilities. with the Resumes of key personnel shall organizational chart.

? The proposal shall identify the location of the Contractor’s

administration and engineering offices for the Work.

? In the event that the Contractor would form a Joint Venture for this project, a list of key

personnel from all companies involved in the Joint Venture shall be submitted for the Owner’s review.