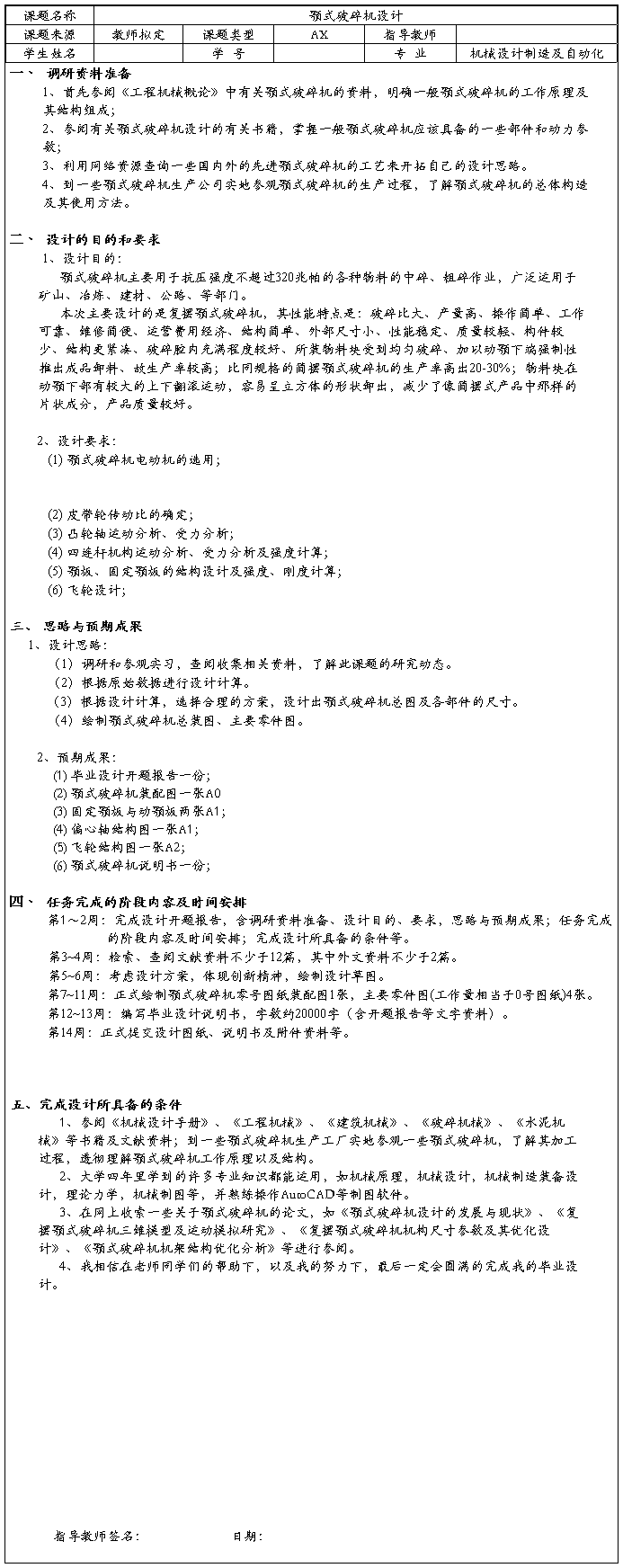

郑州科技学院毕业设计(论文)开题报告

第二篇:颚式破碎机说明书

PE500×750型

颚式破碎机

JAW CRUSHER

使用说明书

OPERATING INSTRUCTION

- 1 -

一、用途 I. Application:

本破碎机用于粗碎、中碎抗压强度极限不超过245MPa的各种岩石或矿石。

The crusher is applicable for the rough and medium crushing of rocks and ores that have a compressive strength not more than 245MPa.

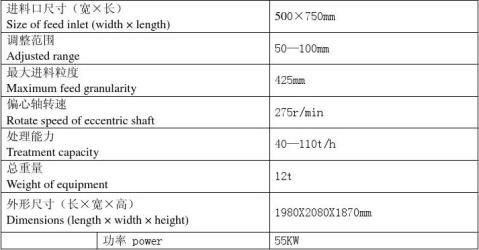

二、主要技术性能

三、结构简述 III. Structure

本机主要由机架、动颚、偏心轴、颚板、肘板等零部件组成。电动机通过三角皮带传动偏心轴旋转,使动颚按照已调好的轨迹进行运动,从而将破碎腔内物料予以破碎。

机架系优质铸钢结构,机架前壁上装有楔

- 2 -

The equipment consists of bracket, jaw, eccentric shaft, jaw plate and ancon plate etc. Eccentric shaft is driven to rotate by motor and jaw runs on adjusted track to crush materials in crushing chamber.

形螺栓紧固的固定颚板。在破碎机左右的机

架内侧壁上装有边护板,以保护机架内侧壁的磨损。

The bracket is high quality cast steel structure. On the front arm of bracket, jaw 颚为一成型铸钢件,正面装有活动颚板,其上部借偏心轴与滚柱轴承悬挂在机架上、下部支承在肘板上,并与肘板成滚动接触,在偏心轴两端装有飞轮和槽轮。

肘板的另一端支承于调整横梁上并与其成滚动接触。肘板除 对动颚起支承作用外,在外来不能破碎的异物,进入破碎腔内时,破碎机负荷物增加的情况下,起保险作用,既自身断裂,从而保护其它机件不变损伤。

调整横梁与机架侧墙电焊钢连接,当排料口调小时,首先放松拉杆弹簧和拉紧螺丝,然后用扳手旋转止动螺钉,使止动螺钉向前顶起垫片组,再插入新增加的垫片,直至所要求的排料口尺寸时,先退回止动螺钉,使垫片组由动颚部件重量压紧,再旋紧拉紧螺钉并紧固定。最后适当旋紧拉杆弹簧,反之则由小变大(抽掉垫片)。

Adjusting beam is welded to side wall of bracket. When the discharge door is adjusted

plate is fixed by wedge-shaped bolt. Edge protection plate is equipped on inside wall of bracket to prevent abrasion.

The jaw is a shaped casting with a kinetic jaw plate on the face. The upper part of jaw is hung on upper and lower parts of bracket and supported on ancon plate by eccentric shaft and roller bearing. There equipped flywheel and grooved pulley at both ends of eccentric shaft.

The other end of ancon plate is supported on adjusting beam. Besides supporting jaw, the ancon plate plays the role of insurance during load increase caused by the uncrushed material’s entry into crushing chamber. It will be broken to protect other pieces from damage.

smaller, release tie spring and tightens screw, rotate retention screw to make gasket up, insert new gasket to achieve required size of discharge door, turn back retention screw to make jaw press closely the gaskets, rotate staybolt and fix it and at last, rotate tie spring tight. Conversely, from small size to large one (draw gasket out).

四、安装说明 IV. Installation

- 3 -

本机由制造厂装配后整机供应的,用户收到产品后就检查,以便消除在运输过程中可能产生的弊病。

1、由于本机工作时振动较大,故建议将机器装在混凝土基础上,为减少振动、噪音和吸振以免机器工作时振动影响建筑基础,最好在破碎机和混凝土基础中间垫以硬木垫板、夹布桐胶带或其它缓冲材料。 2、基础的重量,大致可取为机器重量的5-10倍,地基的深度要大于该处土地冻结的深度,关于机器的安装及地脚螺栓的位置,可参阅基础图。

3、在调整排料口前,应先松开拉紧弹簧,待调整好后,再适当调整弹簧的张紧度,以防肘板在工作时脱落。

The equipment after assembly is provided

by manufacturer and check shall be carried out as soon as receiving product in order to avoid possible troubles during transportation.

1. It is suggested to install the equipment on concrete base to decrease vibration, noise and absorption of shock in order to avoid impact on building base. Adding ironwood, rubber belt or other buffer materials may as well.

2. Weight of base can be determined at 5-10 times of that of equipment and the depth of base shall be more than that of local frozen earth. Refer to the Base figure for locations of installing equipment and foundation bolt.

3. Before adjusting discharge door, release strain spring, and then adjust spring in order to prevent drop of ancon plate.

五、使用须知 V. Notes for use

(一)启动前的准备工作: (I) Preparations before start

1、为仔细检查轴承的润滑情况是否良好,轴承内及肘板的联接处是否有足够的润滑脂。

2、仔细检查所有的紧固是否紧固。 3、传动皮带是否良好,发现皮带有破损现象,应及时更换,当皮带和皮带轮上有油污时,应用干净抹布将其擦净。 4、防护装置是否良好,如发现不安全现象,应立即消除之。

5、检查破碎腔内有无矿石或其它杂物,

- 4 -

1. Check lubrication of bearings and guarantee adequate lubricant inside bearings and on joint of ancon.

2. Check carefully all tightness.

3. Change the abraded belt and clean the oil stain on belt and belt pulley with clean duster cloth.

如有时应清除干净。 (二)破碎机的启动:

1、经检查确认设备传动部分情况正常

方可启动。

2、本机只允许无负荷情况下启动。 3、启动后,如发现不正常情况时,应立即停车查明原因,排除隐患方可再启动。 (三)维护和使用:

4. Cancel unsecured protection devices.

5. Clean ore or other things in crushing chamber.

1、设备运转正常后,方可开始投料。 2、待破碎物料均匀地加入破碎腔内,应避免侧面加料以防负荷不均或单边突增。

3、在正常工作情况下,轴承温升不应超过35℃.最高温度不得超过70℃,否则应立即停车,查明原因加以清除。

4、停车前首先停止加料,待破碎腔内物料排空后,方可关闭电动机。

5、在破碎时,如因破碎腔内物料阻塞而造成停车,应立即关闭电动机,必须将物料清除后,方可再行起动。

6、颚板一端磨损后,方可调头使用。 (四)润滑:

1、经常注意和及时做好摩擦面的润滑工作,可保证设备的正常运转和延长设备使用寿命。

2、本机所采用的润滑脂,应根据机器的使用地点、气温等条件来决定,一般可采用钙基、纳基或钙钠基润滑脂。

3、加入轴承座内的润滑脂为容积的50-70%,每三个月必须更换一次,换油时应用清洁的汽油或煤油仔细地清洗轴承滚柱

- 5 -

(II) Start crusher

1. Start under normal driving conditions. 2. Start only under no load.

3. Stop and get rid of hidden trouble when abnormal thing occurs. (III) Maintenance and use:

1. Feeding equipment after normal running. 2. Material shall be fed evenly in order to prevent side load or side weight increase.

3. Generally, temperature rise o bearing shall not exceed 35℃ and maximum temperature shall not exceed 70 ℃, or stop and get rid of the trouble.

4. Stop feeding before stopping equipment, and cut motor after completely discharging materials in chamber.

5. Cut motor immediately when equipment is stopped by materials block and restart the equipment after completely discharging materials in chamber.

6. Change the abraded end for the other end. (IV) Lubrication:

1. Guarantee friction surface lubricated always in order to keep normal running and prolong service life of equipment.

2. Calcium grease, sodium grease and calcium sodium grease can be applied to the equipment in terms of application location and temperature. 的跑道。

4、肘板与肘板垫接触时,机器开动前必须注入润滑油脂。

3. The added lubricant is 50-70% volume of bearing pedestal and shall be changed every three months. Clean track of bearing roller by clean gas or coal oil when lubricant

is changed.

4. When ancon plate contacts gasket, lubricant shall be added before starting equipment.

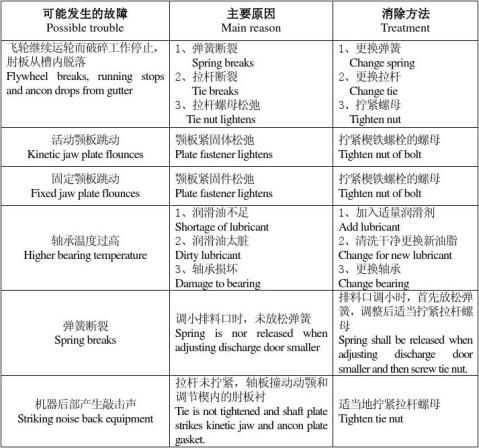

(五)可能产生的故障和消除方法 (V) Possible troubles and treatments

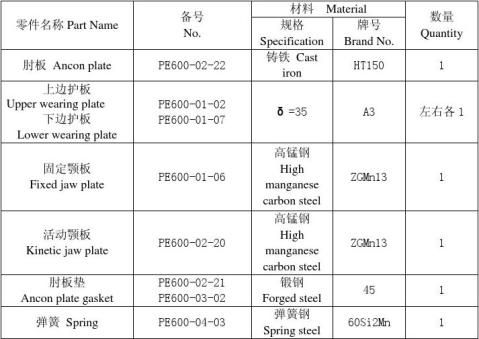

(六) 易损零件明细表

(VI) Wearing parts

- 6 -

六、安全操作规程

VI. Regulations for secure operation

1、操作本机人员,须经安全教育; 2、设备工作时,严禁从上面向机内窥视; 3、设备运转时,严禁作任何调整,清理或检修等工作;

4、设备运转时,严禁用手直接在进料口上破碎腔内搬运或挪移石料;

5、本机的电气设备应接地,并将电线装在绝缘管内。

1. The operators shall be trained with

security education.

2 Looking inwards from upper equipment that is running is forbidden.

3. Any adjustment, cleaning or check is forbidden when the equipment is running.

4. Moving materials by hands in feed inlet or crushing chamber is forbidden when the equipment is running.

5. The electric devices of equipment shall be earthed and line shall be in insulating tube.

- 7 -