通标标准技术服务有限公司深圳分公司 材料实验室

SGS-CSTC Standards Technical Services Co.,Ltd.ShenZhen Branch Materials Lab

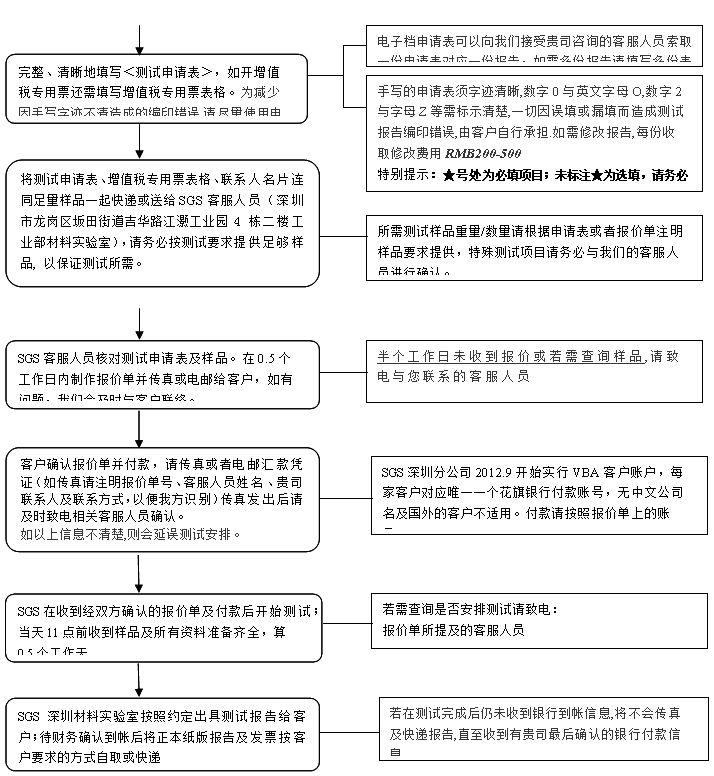

测试申请流程

星期六,日及节假日除外

工作时间:上午: 08:00-12:00

下午: 13:00-17:00

申请流程 注意事项

Materials Lab, SGS-CSTC Standards Technical Services Co., Ltd 通标标准技术服务有限公司

Materials Lab, SGS-CSTC Standards Technical Services Co., Ltd 通标标准技术服务有限公司

地址:中国·深圳·龙岗区坂田街道吉华路江灏工业园4栋二楼,工业部深圳材料实验室

电话( Tel): (86-755) 25328888, ext. 8471/8829/8311/8933/8148/6001/6002/6126/6131 传真(Fax): (86-755) 83197625-0

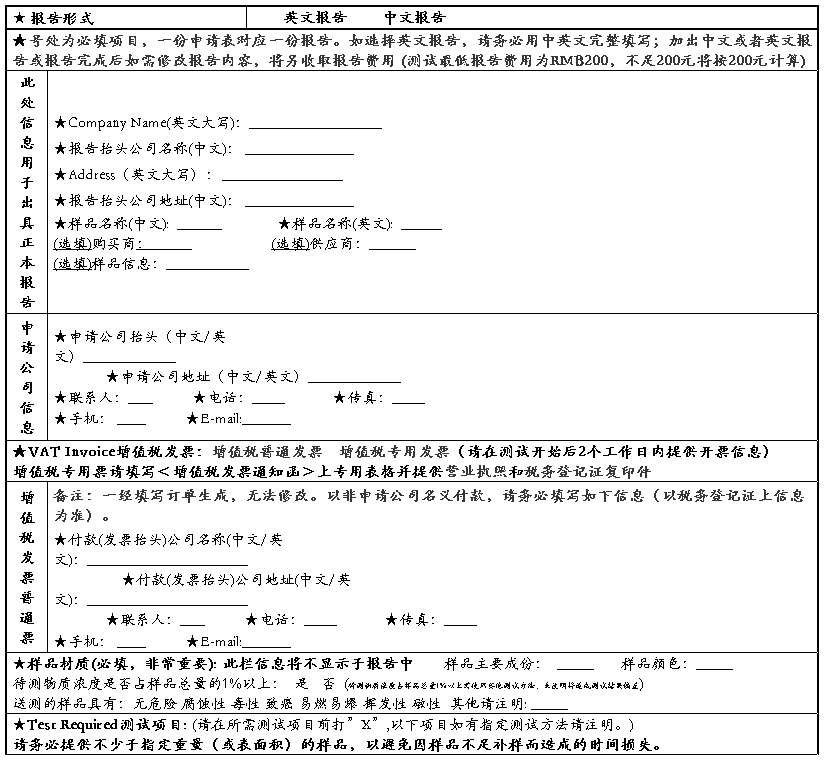

CHEMICAL TESTING APPLICATION FORM

化学类测试申请表

申请人签名确认/日期 SGS代表/日期

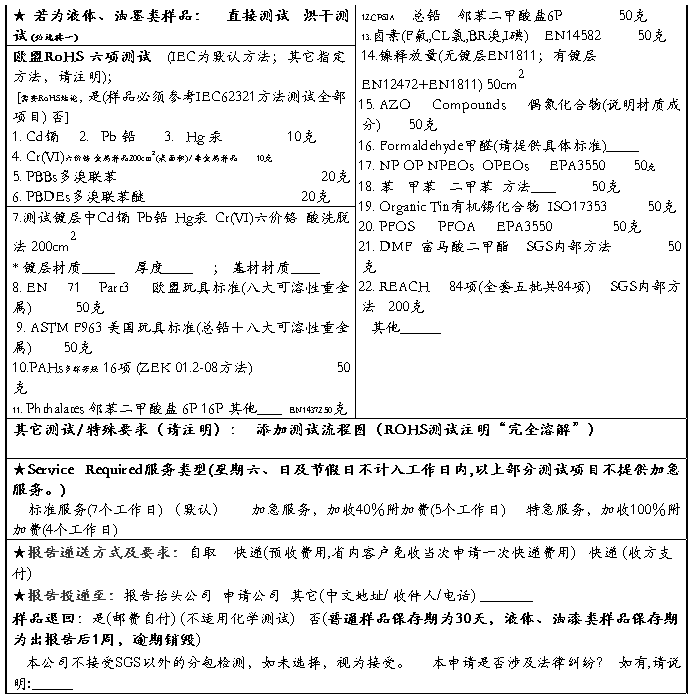

增值税发票通知函

尊敬的客户:

自20##年11月1日起广东省(包括深圳市)将推行《营业税改征增值税试点方案》。由于我公司的业务在增值税试点方案的试用范围之内,我司所提供的服务将按照6%的税率缴纳增值税,并开具增值税发票。按照规定,6%的税率将由购买方承担。

我公司(除培训业务外)的发票分为两种类型,增值税专用发票(可抵扣)和普通发票(不可作为增值税抵扣凭证)。增值税专用发票仅对增值税一般纳税人开具,并作为增值税抵扣的凭证。

如果贵公司作为一般纳税人且需要我司开具增值税专用发票,请贵公司在下表中填写增值税纳税人详细信息,并随同营业执照复印件和税务登记证副本复印件一起扫描、传真或快递给相关客服人员。如在安排测试前未收到回函,我们将认为贵司未登记为增值税一般纳税人,只能开具普通发票。未取得增值税专用发票的,不能在税局取得进项税额的抵扣。

<增值税专用发票填写表格>

请联系贵司财务部确认以上信息,务必填写正确,一经填写订单生成,无法修改。如您已填写过一次,则不用重复提交!

顺祝商祺!

通标标准技术服务有限公司工业部材料实验室

第二篇:20xx SGS RoHS F20-03

Test Report No. F690101/LF-CTSAYAA12-00074

To:KOREA ENGINEERING PLASTICS (ULSAN)

578-26

Maeam-dong

Nam-ku

Ulsan

KoreaIssued Date:2012. 01. 05Page 1 of 4

The following merchandise was submitted and identified by the client as :

SGS File No.

Product Name

Item No./Part No.AYAA12-00074: KEPITAL 1: :F20-03

F10-01, F10-02, F10-03H(M/LOF), F10-01 T2, F10-52, F15-33(LOF), F20-01, F20-02, Client Reference Data : F20-03(M/LOF), F20-33(LOF), F20-52(G/LOF), F25-03(M/LOF), F25-03H(LOF),

F25-03HT(LOF), F25-63(LOF), F30-01, F30-03(M/LOF), F30-34(LOF), F30-52(G), F40-03, TX-11H(LOF), TX-11HK(LOF), TX-21(LOF), TX-31(F/LOF), FV-40(LOF), MX20BT01, MX25BT01, MX30BT01, F10-52H, F10-52D

Received Date : 2012. 01. 02

Test Period :2012. 01. 03

Test Results

Test Performedto2012. 01. 05: For further details, please refer to following page(s):SGS Korea tested the sample(s) selected by applicant with following results.

SGS Korea Co. Ltd.

Timothy Jeon

Jinhee Kim

Cindy Park

Jerry Jung/ Testing Person

Jeff Jang / Chemical Lab Mgr

F052 Version4

Test Report No. F690101/LF-CTSAYAA12-00074

Sample No.

Sample DescriptionItem No./Part No.Materials Test ItemsCadmium (Cd)Lead (Pb)Mercury (Hg)

Hexavalent Chromium (Cr VI)

Issued Date:2012. 01. 05Page 2 of 4

:AYAA12-00074.001:KEPITAL 1:F20-03:N/A

Unitmg/kgmg/kgmg/kgmg/kg

Test Method

With reference to IEC 62321:2008, ICPWith reference to IEC 62321:2008, ICPWith reference to IEC 62321:2008, ICPWith reference to IEC 62321:2008, UV-VIS

MDL0.5521

ResultsN.D.N.D.N.D.N.D.

Test Items

MonobromobiphenylDibromobiphenylTribromobiphenylTetrabromobiphenylPentabromobiphenylHexabromobiphenylHeptabromobiphenylOctabromobiphenylNonabromobiphenylDecabromobiphenylMonobromodiphenyl etherDibromodiphenyl etherTribromodiphenyl etherTetrabromodiphenyl etherPentabromodiphenyl etherHexabromodiphenyl etherHeptabromodiphenyl etherOctabromodiphenyl etherNonabromodiphenyl etherDecabromodiphenyl ether

Unitmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kg

Test Method

With reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MSWith reference to IEC 62321:2008, GC-MS

MDL55555555555555555555

ResultsN.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.N.D.

NOTE:

(1) N.D. = Not detected.(<MDL)(2) mg/kg = ppm

(3) MDL = Method Detection Limit(4) - = No regulation

(5) * = Boiling-water-extraction:

Negative = Absence of CrVI coating

Positive = Presence of CrVI coating; the detected concentration in boiling-water-extraction solution is equal or greater than 0.02 mg/kg with 50 cm2 sample surface area.

This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

F052 Version4

Test Report No. F690101/LF-CTSAYAA12-00074

Issued Date:2012. 01. 05Page 3 of 4

Picture of Sample as Received:

NOTE:(1) N.D. = Not detected.(<MDL)

(2) mg/kg = ppm

(3) MDL = Method Detection Limit

(4) - = No regulation

(5) * = Boiling-water-extraction:

Negative = Absence of CrVI coating

Positive = Presence of CrVI coating; the detected concentration in boiling-water-extraction

solution is equal or greater than 0.02 mg/kg with 50 cm2 sample surface area.

This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

F052 Version4

Test Report No. F690101/LF-CTSAYAA12-00074

PBBs/PBDEs

Mechanic_Sample

Issued Date:2012. 01. 05Page 4 of 4

Testing Flow Chart for RoHS:Cd/Pb/Hg/Cr6+/PBBs&PBDEs TestingCd/Pb/Hg

Mechanic_Sample

Cr6+

Mechanic_Sample

Cr6+

Mechanic_Sample

Sample Measurement Sample Measurement

Sample Measurement

Sample Measurement

Acid Digestion with Microwave/Hotplate

Solvent Extraction of the SampleClean-up with Florisil

Column

Nonmetallic Material

Metallic MaterialSpot Test / Boiling Water ExtractionAdding 1,5-Diphenylcarbazidefor Color Development

Adding Extraction Solution

FiltrationResidue

of Extraction Solution

Heating to 90~95°C for Extraction

Filtration and pH Adjustment

Total Digestion

Filtration

for Color Development

the Presence of Cr6+

ICP-AES/AAS/MS

GC/MS

UV-Vis

DATA

Confirmwith UV-VisDATA

DATA

The samples were dissolved totally by pre-conditioning method according to above flow chart for Cd,Pb,Hg. Section Chief : Gilsae Yi

*** End ***

NOTE:

(1) N.D. = Not detected.(<MDL)(2) mg/kg = ppm

(3) MDL = Method Detection Limit(4) - = No regulation

(5) * = Boiling-water-extraction:

Negative = Absence of CrVI coating

Positive = Presence of CrVI coating; the detected concentration in boiling-water-extraction solution is equal or greater than 0.02 mg/kg with 50 cm2 sample surface area.

This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

F052 Version4