*************** Co. Ltd

Room 5-604, Art and Technology Centre, No.95 Haire Road, Qingdao, China

Tel: +86-532-80978612

Fax: +86-532-80978246

Inspection Report

Report Ref. No.: SZXWT00289440

Buyer: VIDEORTS LTD, 1715 SOFIA,MLADOST-4, BULGARIA.

Supplier:

Product Description: 7” TFT LCD TV; 9”TFT LCD TV.

Inspection Location: Shenzhen Inspection Date: 14/04/2012

Reference Sample Provided: N/A

OVERALL INSPECTION CONCLUSION: Subject To Client’s Decision

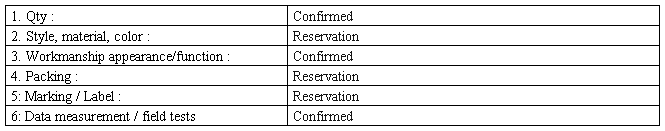

INSPECTION SUMMARY(In comparison to principal’s instructions and reference sample, as provided)

Reservation:

1. No Client’s approval sample was available for inspection reference.

2. We only perform the quantity check and visual check for this lot during inspection.

3. No warning words were found on polybag during inspection, but the punch hole, recycle mark and green mark were found on the polybag.

4. Zoom function was only available for the JPG files at “CARD/USB” mode.

5. AV out function was only available at “CARD/USB” mode.

6. For item: JV-VC118A, the default language of TV menu was English.

7. No client’s LOGO was found on the remote controller.

8. Only 1ctn spare parts were ready for inspection. .

INSPECTION METHOD APPLIED:

ANSI/ASQC Z1.4-2003, Single sampling plan for normal inspection at Level I ,

Acceptable Quantity Level(AQL) for: Critical N/A Major: 2.5 Minor: 4.0

Sample size inspected: 32 for Maj/Min

Samples selected from carton numbers: Total 15 cartons were selected randomly.

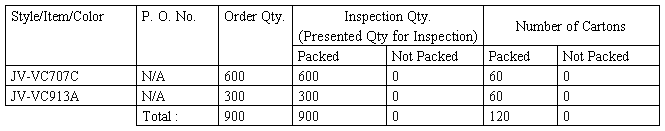

1. QUANTITY

2. PRODUCT CONFORMITY

2.1 Style conformity: Confirms

2.2 Material conformity: Reservation

2.3 Color conformity: Reservation

(See photos)

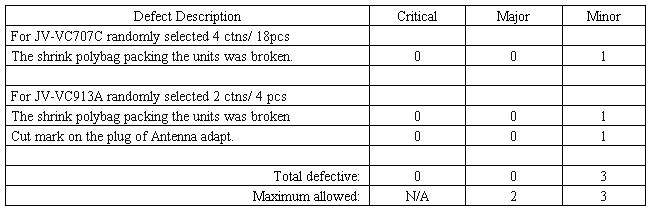

3. WORKMANSHIP APPEARANCE/FUNCTION INSPECTION FINDINGS:

Requested AQL Critical defective maximum allowed: 0 within AQL.

Major defective maximum allowed: 2 within AQL.

Minor defective maximum allowed: 3 within AQL.

4. PACKING

4.1 Individual packing conformity: Actual finding

For 7”

Each set was protected with the polybag and packed into white box with the manual, then packed into the giftbox with the white accessories box.

4.2 Inner packing conformity: N/A

4.3 Export packing conformity: Actual finding

7” 10pcs/carton

9” 5pcs/carton

5. MARKING / LABEL

5.1 Bar code: Confirmed

Refer to the attached photos.

Check Barcode with barcode scanner at site, the result was acceptable.

5.2 Shipping mark conformity: Actual finding

Refer to the attached photos.

5.3 Other marks

5.3.1 Side mark conformity: Actual finding

Refer to the attached photos.

6. PRODUCT-SPECIFIC DATA MEASUREMENTS / FIELD TESTS ON REDUCED SAMPLE SIZE(as applicable for specific product or order)

6.1 The following tests were performed on Level I (32pcs samples) during inspection.

6.1.1 Packing/visual check found within AQLs.

6.1.2 According to the client’s inspection requirement, we only inspect these units with visual and quantity check was found acceptable except of defect shown on point 3 AQLs.

6.2 The following tests were performed on 1pcs sample or one carton for each model during inspection.

6.2.1 Technical data measurement test found can not be proceed due to no suitable equipment provided.

6.2.2 For JV-VC707 Size of carton: 63*24*35mm Size of gift box: 22*12*16mm

Weight of carton: 11.32Kg.

6.2.3 For JV-VC913 Size of carton: 61*28*20mm, Size of gift box: 27*15*18mm

Weight of carton: 7.8Kg.

7. INFORMATIVE REMARKS:

7.1 Total 1100pcs packed units were ready for our inspection.

7.2 We check the quantity and models inside the cartons, the result was found acceptable. Please refer to the attached photos.

7.3 No seal label was found on the checked cartons during the inspection.

7.4 Only 1 ctn spare parts were ready for the inspection(1% spare part packed, included 11 pcs Antenna, 11pcs car adapters. )

8. ATTACHMENTS:

Please refer to the attached photos.

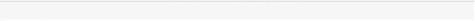

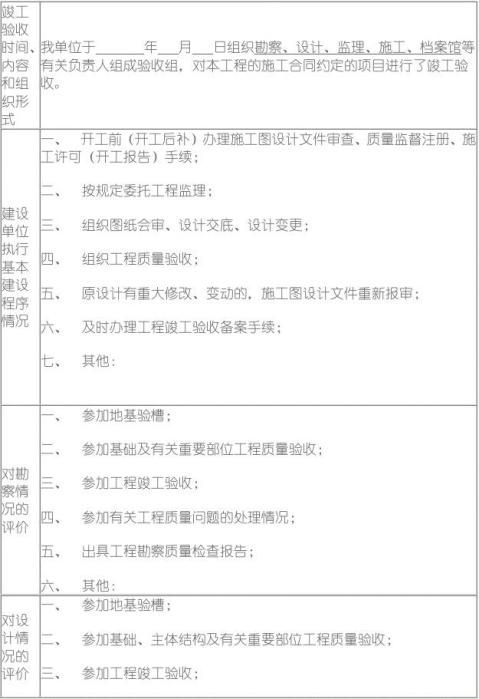

第二篇:验收报告格式

工厂竣工验收报告样本