The Structure Optimization of the Siphonic Bedpan’s Flow Channel Based on the Numerical Simulation Technology

Ge Zhenghao, Wang Jinshui,Su Penggang , Liang Jiangbo

Shaanxi University of Science & Technology, Xian, Shaanxi, 710021, China

gezh@qq.com

Abstract—According to siphonic bedpan’s work principle, siphonic bedpan with variational section flow channel is put forwards into application in this paper. Structure design optimization of siphonic bedpan’s flow channel is discussed. Based on making use of Pro/E to conduct the parametrization modeling of the siphonic bedpan (the constant section bedpan and the variational section bedpan), and then adopt ADINA to simulate the flow field in the siphonic bedpan with not taking the filth into consideration. The calculation results of the numerical simulation demonstrate that variational section bedpan is better than the constant section bedpan in flushing and saving water. The results indicates the adoption of ADINA software to carry out sanitary implement’s numerical simulation can improve the accuracy of the bedpan design and manufacturing consumedly, provides a theories analysis foundation for the engineering, design and application of bedpan.

Keywords-Siphonic Bedpan;Flow Channel Structure; Numerical Simulation

I. Introduction

The software ADINA is the product of the American company of ADINA, it is a large numeric calculational system based on the finite element method. It computes the engineering problems that various structure, fluid, the temperature field and several field coupling by solving various physical basic controlling equation. This paper recurs to the Pro/E and ADINA, making use of the parameterization design and numerical simulation, have researched siphonic bedpan’s best structure of flow channel.

II. Flushing function requirement of sanitary implement

With the improving of the people’s life, the request to the sanitary implement is becoming higher and higher. At the same time, it is requested that: (1) full fill the essential function, (2) stress the shape beauty, and (3) saving water. The quality of the sanitary implement has been requested to include exact size tolerance, fine external appearance, physics function, flushing function etc. Flushing function is the ability that the bedpan ejects filth, washes it clearly while controlling the amount of water. Without question, flush function is one of the uppermost functions. According to the flushing way, bedpan can be divided into wash-down type, siphonic type and ejecting siphonic type. Wash-down bedpan rush out filth by the impact of the water, the power is decided by potential energy of the water in tank subtracts losing energy. Siphonic bedpan’s flush power primarily relies on siphonic power.

III. The structure design of siphonic bedpan’s flow channel

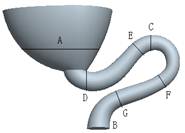

As mentioned above, under the condition of piping water-filled, whatever means we adopt, it will not produce the siphonic phenomenon if air is interfused. So we should make sure that the piping section dimension is appropriate, as figure 1 shows, the diameter of D-E segment is degressive.

According to the statics and hydromechanics theories, while the fluid in piping flows stably, the physical volume flux is constant at any section of the pipe. So the smaller of the pipe section, the higher of the current velocity of the fluid. So the diameter change could result in the water velocity change in the D-E segment.

Figure 1. The structure design of siphonic bedpan’s flow channel

Thus at the beginning of the siphonic bedpan’s flow channel, the flushing velocity of the water becoming higher and higher, form the E-F segment in advance, expedite siphonic process, reduce the amount of water, attained the purpose of saving water. The D-E segment is rising, and its section diameter is generally among 55-65 mm. The ability of rushing out filth will be weakend with larger diameter, the result may increase water amount. While the drainage amount in forepart will be influenced with smaller diameter, it will cause the water surface rising, and result in siphonic phenomenon later. The E-F segment is a hump segment, its perfect section diameter generally among 45-55 mm. The F-G segment is a increasing segment, the diameter is becoming bigger from small, and the section is becoming large, it will lower the current velocity of the fluid, make siphonic segment’s length increase, in addition make siphonic phenomenon keep more time, And its section diameter is generally among 55-60 mm.

IV. Three-dimensional Steady Numeric Simulation for flowing in bedpan

Bedpan’s geometrical modeling is the most complicated in sanitary implements, its CAD model include complicated surface and characteristics, these may result in many difficulties during the numeric simulation and influence the result. Considering the siphonic bedpan’s whole flow channel as computing area, and the difficulty to set up the CAD model in ADINA, so this paper make use of Pro/E to conduct the parameterization model of the siphonic bedpan. The water warp is 200 mm high, and the pipe diameter in the largest section is 80 mm.

Then the model is imported into ADINA8.3 through IGES data format. In ADINA, we still need to predigest the physics model before adding load and boundary conditions. Detailed information is as follows:

Load: velocity (the water warp’s entry velocity is 1.5 m/s),

Pressure (Pressure in piping exit),

and in addition,

Special boundary condition is wall.

The material is water, and its

density is 1.0×103 kg/m3,

viscosity is 1.003×10-3 kg/(m·s).

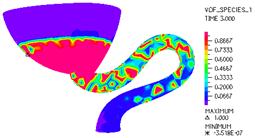

In ADINA, tetrahedral grid is adopted, and the model is meshed according to appointed unit length being 2 mm to the sections with same diameter. To the constant section bedpan, total meshing grid node amount is 3378, meshing grid unit amount is 15497, and to the variational section bedpan, meshing grid node amount is 2968, meshing grid unit amount is 13818. Appointed time step is 100, constant magnitude is 0.1 S, the calculation results are showed as the figure 2 and 3.

Figure 2. Pressure distributing for the constant section bedpan

Figure 3. Pressure distributing for the variational section bedpan

Comparing the above two calculation results and in regard to pressure and velocity, in the approximate same position, the variational section bedpan obviously excelled the constant section bedpan. To the constant section bedpan, the maximal pressure is 7.3 E+06(Pa), the upmost velocity is 42.32 m/s, the pipe’s exit maximal pressure is -77583 Pa, to the variational section bedpan, the maximal pressure is 2.178E+08(Pa), the upmost velocity is 193.2 m/s, the pipe’s exit maximal pressure is -227620 Pa. Analyzing siphonic bedpan’s flow channel structure, because of the rising segment, hump segment and descending segment, rising segment diameter is becoming smaller, thus in the beginning of the D-E segment, the water velocity becoming more and more high, filled the hump segment in advance, siphonic process was occurred rapidly. So make the siphonic pressure increase consumedly, and enhance the siphonic power, attained the purpose of saving water.

V. The VOF analysis on siphonic bedpan’s flushing process

A. The VOF Method

The VOF (Volume of Fluid) method is defined such a volume fraction F, defining the value of the point having fluid as 1, the value of the point having no fluid as 0. Thus, in a mesh unit, the F average value represents the quota that fluid contained the unit. If the average value is 1, the mesh is filled with the fluid, if the average value is 0, then for empty mesh. If the value is between 0 and 1, the mesh is free surface mesh. So it has advantages of easy realization, small calculation quantity, high-precision etc, and can handle complex nonlinear problem such as free surface folding, free surface filling water etc. When the model involves flow theories of the two phases or multi-phase, it introduces the single fluid model to solve problem. Namely, in the water-air two phase flow field, water and air obey the same team momentum equation. In the computing area, each controlling volume is filling with water and air, and their volume fraction’s addition should be 1, namely,

Among above, ‘a’ denotes the volume fraction, subscript ‘w’ and ‘a’ denote water and air respectively. Once the water and air’s volume fractions are known, all their unknown quantity and characteristic parameter can be denoted by average volume fraction. Tracking the water-air interface can be solved by nether consecutive equation.

Thereinto, ‘V’ denotes velocity vector.

B. Boundary conditions

The material property and the boundary conditions are as follows: Gas phase is air, and its density is 1.293 kg/m3, viscosity is 1.7894×10-5 kg/(m·s). Liquid phase is water, its density is 1.0×103 kg/m3, viscosity is 1.003×10-3 kg/(m·s). The work pressure is 101325 Pa. Gravitational acceleration is -9.8 m/s2, work density choose the lighter phase’s, to obviate water static pressure calculation in the lighter phase, it need to improve the precision of momentum balance calculation.

C. The result for bedpan’s VOF analysis

According to the above computing conditions, defining initial condition is, water tank and water envelop are all filled with water, and we can get the result of the bedpan’s flushing process in 0-6s.

1) Flushing proces

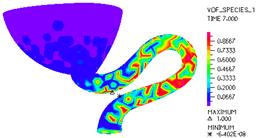

The figure 4 shows flowing field distributions at different moment.

Figure 4. Distributing of flow at different moment by simulation for the variational section bedpan

In the figures above, areas in red colour represent water, areas in navy blue represent air, other colours represent the mixture of water and air. Contrasting the flow field distribution of the constant section bedpan to the variational section bedpan, we will found, to the constant section bedpan, during 0-5s, water caput hasn’t gotten across the pipe’s tiptop while to the variational section bedpan, water caput has already gotten across during 0-1s and in 5.6 s, water in the warp has flowed out completely. This mainly because when the water caput got across the pipe’s tiptop, the siphonic phenomenon happens. Water warp’s outflow increases largely. This makes water level drop rapidly and reach lowest level in warp, and then the siphonic phenomenon stops, water velocity becomes lower, water that has not gotten across the pipe’s tiptop start to turn back, and finally become level off.

2) Pressure distribution

The figure 5 shows pressure distribution at different moment for the variational section bedpan. In the following figures, to the constant section bedpan, the minus pressure is -695.4 Pa, while to the variational section bedpan, the minus pressure is -1733 Pa, this difference shows the strong function of siphon.

Figure 5. Pressure distributing at different moment for the variational section bedpan

3) Velocity distribution

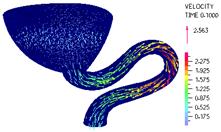

As the figure 6 shows, velocity for the variational section bedpan is averagely larger than the velocity for the constant section bedpan, consequently, it provide effective gist for variational section bedpan, it can easily achieve effectively flushing aim compared to the constant section bedpan. Besides, it indirectly indicates that the variational section bedpan can easily achieve the function of saving water.

Figure 6. The velocity distribution of the two kind sections bedpan pipe

VI. Conclusions

This paper studied on the structure optimization of the siphonic bedpan’s flow channel, recurring to finite element software ADINA, three-dimensional steady flow numeric simulation of water flowing in bedpan is carried out, the VOF analysis on siphonic bedpan’s flushing process has also been carried out. The results can help technics designers find out the disfigurement essentially, enhance the precision in the porcelain sanitation field. Further more, it will shorten the exploiting time and expense of the new product consumedly, bring remarkable economic benefit to producing enterprise.

Acknowledgment

The preferred spelling of the word “acknowledgment” in America is without an “e” after the “g”. Avoid the stilted expression, “One of us (R.B.G.) thanks . . .” Instead, try

“R.B.G. thanks”. Put applicable sponsor acknowledgments here; DO NOT place them on the first page of your paper or as a footnote.

References

[1] Yue bangguo, “Talking about bedpan’s flushing filth function and saving water,” Chinaware, 2001(5).(in Chinese)

[2] Wu ziniu, The basic elements of computing hydromechanics. Beijing: the Science Press. 2001. 1-8. (in Chinese)

[3] Hong fangwen, “Kinetic object round free surface flowing field value simulation and experimentation research,” Doctor Degree thesis. Wuxi, Jiangsu, China: Chinese watercraft science research center. 2001.4. (in Chinese)

[4] C.W. Hirt, B.D. Nichols. Volume of fluid (VOF) method for the dynamics of free boundaries. Journal of Computational Physics, 1981, 39:201-225.

[5] Lin huzong, Phantasmagoric flowing science-multiphase hydromechanics. Beijing: the book concern of Qinghua University, Guangzhou: the book concern of Jinan University. (in Chinese)

[6] Wang youcheng, Shao min, The theory and numeric method on finite element analysis. Beijing: the book concern of Qinghua University, 1997. (in Chinese)