Factory Quality Assessment

Audit Report

(验厂报告)

The Vendor Certification process will begin with an audit of all current manufacturing facilities and their processes. It incorporates a grading system, which will be used as a guide for selecting and improving Staples’ suppliers of own brand products.

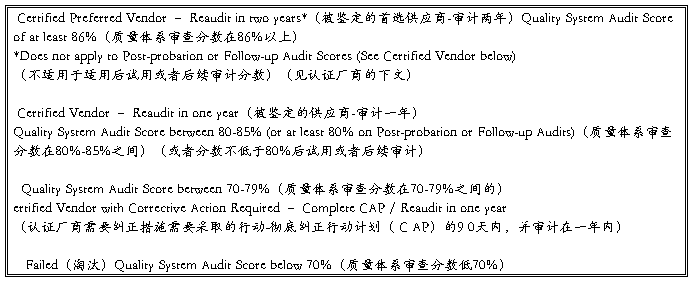

Outlined below is the Auditing Rating Scale, the criteria and associated auditing and follow-up frequency.

供应商认证过程中,将首先与审计目前的所有生产设施和流程。它结合了分级制度,这将用来为指导,选拔和改进供应商的自有品牌产品。

下文列举了审计评价尺度,标准和相关的审计和后续审计。

personnel or our designated representative will perform all Audits and CAP follow-ups.人员或我们指定的代表将履行所有审计和彻底纠正行动计划的后续追踪。

Factory Information

Factory Name:(工厂名称)_____________________________________________________

Company name:(公司名称)__________________________________________________

Telephone:(电话) Fax:(传真)

E-mail(电子邮件) Contact Person:(联系人)

Factory has been in operation since(工厂成立时间)

Major Machinery: Amount Remarks:

(主要机器设备) (数量) (备注)

Type of Audit审计类型:( ) Initial Qualification 初始认证 ( ) Critical Issue or CAP Follow-up Audit 关键的问题,或者CAP后续审计( ) Recertification Audit换发新证审计 ( )Post-probation Audit试用审计( ) Other (please specify):其他,请指出:

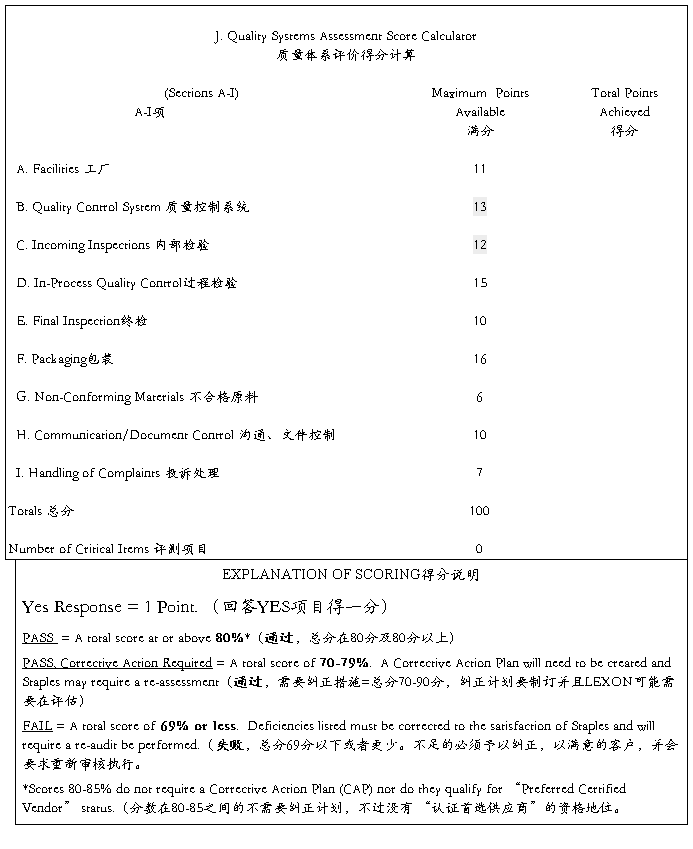

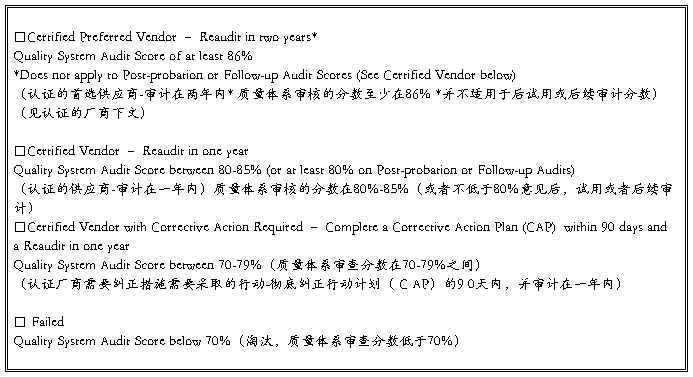

SCORE OF THE QUALITY SYSTEM AUDIT

STATUS AND NEXT ACTION DUE

COMPANY ORGANIZATION Met during Audit?

公司组织机构 审计期间会见?

Managing Director/General Manager(懂事/经理) ( )Yes ( ) No

Sales Manager/Marketing Manager业务/市场经理 ( )Yes ( ) No

Plant Manager(车间主管) ( )Yes ( ) No

QC/QA Supervisor/Manager(QC/QA/及主管) ( )Yes ( ) No

Production Manager/Factory Manager(厂长) ( )Yes ( ) No

STAFFING INFORMATION

(内部员工信息)

Manufacturing Personnel:

生产工人:

Quality Controllers:

QC:

Engineers:

技术人员:

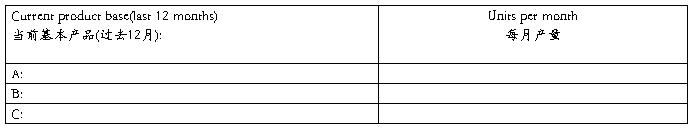

PRODUCTION INFORMATION(生产信息)

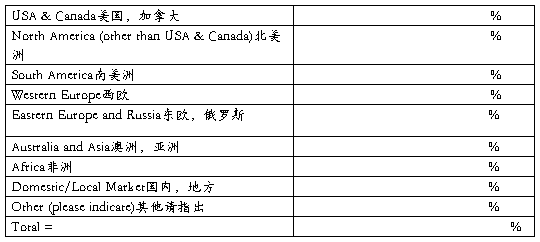

Major Customers(主要客户:)_______________________________________________________

Monthly Production Capacity(平均每月产量:)_________________

Produce Peak season(s)( 生产旺季 ) From从:_______ To至:_______

Which kind of quality certificate test report did factory pass?

工厂有没有通过一些相关的认证: _____________________________________

How many operators per line?每条线有多少工人 : ________________________

How many Quality Controllers per line

每条线上有多少QC : __________________________________

What is the production sq.ft / sq.mtrs?

生产区域面积:__________________________________

“Yes” answers score 1 point. “No” answers scores 0 points.

“是”答案得一分,“不是”答案不得分。

A. FACILITIES(设备)

1. Does the plant layout appear generally acceptable? ( ) Yes ( ) No

(车间布置基本上可以接受吗?)

2. Does the overall maintenance of the premises ( ) Yes ( ) No

appear acceptable?

(是否整体厂房维护似乎可以接受?)

3. Does the general housekeeping appear acceptable? ( )Yes ( ) No

(车间一般的内务管理看上去还可以接受吗?)

4. Did you see a complete company policy manual? ( ) Yes ( ) No

(您有没有看到一个完整的公司政策方针手册?)

5. Did you see documentation that all production ( ) Yes ( ) No

machines were on a maintenance schedule and

a maintenance team was in place

(你看到生产设备维护时间表和工厂的维护队伍了吗?)

6. Does the factory have a back up generator? (If yes, ( ) Yes ( ) No

provide date of last use and date of last maintenance

below). __________________________________

(工厂是否有备用发电设备)(如果有,请提供最后使用的日期和最后维护的日期)

7. Did you see that all machines/equipment/fixtures ( ) Yes ( ) No

were suitable to produce the intended products?

(你觉得所有的机器、设备、装置适合目前即将要开始的定单产品吗?)

8. Did you see evidence that the factory has a well ( ) Yes ( ) No

organized maintenance team that could immediately

respond to a machinery breakdown or emergency?

(你觉得工厂有个良好的保养组可以对机器损坏或者紧急情况做出快速反映吗?)

9. Did the lighting and ventilation conditions appear ( ) Yes ( ) No

adequate in the production areas?(生产区域是否足够的光照及良好的通风条件?)

10. Did you confirm that fax and telephone were ( )Yes ( ) No

available?

(可以用电话和传真联系到工厂吗?)

B. QUALITY CONTROL SYSTEM

(质量控制体系)

1. Did you see evidence that the factory has a formal ( ) Yes ( ) No

internal quality control program for all of its products?

(有没有证据证明工厂在所有的产品生产都有明显的内在质量控制体系来维系?)

2. Did you see evidence that there is a formal internal ( ) Yes ( ) No

training program for all quality control (QC) personnel?

(有没有给所有QC内部培训的正式的程序的证据?)

3. Did you see formal training records for all QC personnel? ( ) Yes ( ) No

(看到过给QC培训 的一些正式培训记录?)

4. Were all QC personnel certified before they were allowed ( ) Yes ( ) No

to perform their jobs?

(全部的QC人员被鉴定后才获准履行其工作?)

5. Are the QC personnel independent of the production staff? ( ) Yes ( ) No

(QC是不是只单独做检验的工作人员?)

6. Did you see a complete Quality Manual? ( ) Yes ( ) No

(你看到工厂有一个完整的品质手册吗?)

7. Did you see that the factory is using international, national, ( ) Yes ( ) No

client’s, and/or its own approved standards to perform

in-house quality control?

(你看到工厂正在用国际、国家的、行业标准或者自己制定的检测标准来进行内部的质量控制吗?)

8. Did you see detailed written plans demonstrating how ( ) Yes ( ) No

safety requirements of products are checked in-house?

(你有没有看到详细的书面计划,说明如何对有安全要求的产品进行检查)

9. Did you see detailed QC reports that reflect all products ( ) Yes ( ) No

are being properly checked/inspected?

(你看到详细QC的检验报告反映所有的产品都经过适当的检查了吗?)

10. Did you see evidence that there was adequate QC ( ) Yes ( ) No

supervision on all shifts?

(有没有证据证明有足够的QC来监督所有的轮班吗?)

11. Was there evidence that all QC personnel fully ( ) Yes ( ) No

understand quality policy, quality consciousness and

the importance of the quality assurance concept?

(所有质量控制人员是否充分了解产品质量方针、是否具备良好的质量意识。以及质量保证观念的重要性?)

12. Does QC have adequate basic knowledge and expertise ( ) Yes ( ) No

on products and general manufacturing technology?

(QC是否有适当的对产品的基本知识和专业知识以及一般制造工艺?)

13:Did you see documentation that the factory had all ( ) Yes ( ) No

relevant international/national safety standards and was

in compliance?

(看到工厂是否持有所有相关的国际、国家的安全标准,是否有遵循?)

C. INCOMING MATERIALS INSPECTIONS

(采购原料检验)

1. Was there evidence that the factory takes adequate ( ) Yes ( ) No

measures to assure raw materials conformance to

required specifications before use?

(是否有证据表明,工厂需有适当的措施,以确保原料符合所需的规格,然后才开启使用?)

2. Are raw materials properly labeled, stored and traceable? ( ) Yes ( ) No

(是原料妥善标示,贮存及可追踪的?)

3. Are raw materials kept in controlled storerooms to avoid ( ) Yes ( ) No

theft, loss and any deterioration of quality?

(原料存放在储物室保存,能避免盗窃,损失和任何质量退化吗?)

4. If raw materials need inspection before putting into ( ) Yes ( ) No

production, are they properly inspected and are records

traceable?

(如果原料在进仓前需要检查,工厂是不是有适当的检查,已经记录可循?)

5. Do records show that rejected lots are well identified, ( ) Yes ( ) No

segregated from acceptable lots and eventually returned

to the supplier?

(有没有记录显示哪些是接受的,哪些原料返回了供应商?)

6. Is the inspection sampling schedule adequate and can the ( ) Yes ( ) No

quality of the product be guaranteed with confidence?

样品检查时间是否充足,样品质量能予保证?

7. Are adequate inspection records maintained to prove ( ) Yes ( ) No

products are checked and meet all requirements?

(是否有适当的检验报告证明产品被检验了,而且都能满足要求吗?)

8. Are there adequate written inspection instructions ( ) Yes ( ) No

with proper accept/reject criteria available as guidelines to inspectors?

(检查指示有可以给检验人员适当的接受和不接受的标准吗?)

9.If testing equipment is needed during inspection, is it ( ) Yes ( ) No

sufficient, in good condition and calibrated?

(如果 在检查中需要一些检测设备,这些设备数量是否是充足的、机器情况良好的以及是被校准的?)

10. Is there a systematic control on the non-conforming ( ) Yes ( ) No

raw materials and is it efficient?

(是否有一个有系统的控制对不合格原料及其是否有效?)

11. Does the factory have a formal process for selecting and ( ) Yes ( ) No

qualifying new suppliers?

(公司是否有对筛选的供应商和新的供应商有个正式的筛选的程序)

12. Does the factory have a formal process for continuously ( ) Yes ( ) No

monitoring a supplier’s performance?(公司是否有不间断监视供应商执行相关规定的程序)

D. IN PROCESS QUALITY CONTROL

(过程质量控制)

1. Did you review an outline of the various steps of ( ) Yes ( ) No

the manufacturing process?

(你可以看到各个工艺的制造步奏过程的大纲吗?)

2.Are samples of pilot runs carefully reviewed by ( ) Yes ( ) No

engineers and quality staff to see all quality and safety aspects are being met?

(是样本是否仔细审查,由工程师和高素质的工作人员看到所有的质量和安全方面是否得到满足?)

3. Is there sufficient well trained In-Process QC staff ( ) Yes ( ) No

to prepare for mass production

(是否有足够训练有素的QC准备于大规模的生产过程中?)

4. Is there documentation from either engineering, the ( ) Yes ( ) No

QC department, or top management to authorize

mass production?

(大规模生产有来自工程部、质量部或者高管理层的批示的书面文件吗?)

5. Are the production lines checked by QC (or by other ( ) Yes ( ) No

means) to monitor the compliance of the product to

meet quality and safety requirements?

(QC是否对生产线进行检查(或其他手段),以监察其生产的产品是否能符合相关质量和安全要求?)

6. Does the factory use international (or other approved ( ) Yes ( ) No

standards) to carry out in-process inspection and are

there records?

工厂在过程检查中是否遵循相关国际标准(或者其他认可的标准),以及是否有记录?

7. Do records reflect the action taken on the rejected ( ) Yes ( ) No

lots?(记录确实有反映被拒绝的部分的记录吗?)

8. Do records show rejected lots are well identified and ( ) Yes ( ) No

are they segregated from accepted lots

(记录中是否显示不良品被很好的鉴别出来并且和合格品分开放置的?)

9. Are rejected lots immediately segregated and marked ( ) Yes ( ) No

for recycling or destruction?

(不良品是否能迅速的被隔离,以及做上标记指示用于再利用还是报废)

10. Are there adequate, clearly written criteria/instructions ( ) Yes ( ) No

with proper accept/reject criteria available as guidelines

to inspectors?

(是否有足够的,明确的书面标准/指示适当的接受/拒绝标准,作为指引给检验人员?)

11. Are there adequate approved samples available in all ( ) Yes ( ) No

areas to give inspectors and workers guidelines?

(是否有充足被核准的样品给各区域的验货员和工人作为指引?)

12. Are adequate work instructions available to all ( ) Yes ( ) No

employees defining the manner of production, assembly

specifications, machine settings, etc.?

(有没有足够的工作指示提供给所有雇员界定的方式生产,组装规格,机器设置等?)

13. Are engineering and specification changes reviewed ( ) Yes ( ) No

and approved by authorized personnel prior to

implementation?

(工程和规格的变化,通过授权的人员讨论并核准后实施?)

14. Is there a sufficient on-site test facility that is capable ( ) Yes ( ) No

of checking the quality of the product and the

conformance of finished goods? (list which testing

methods are being used – i.e. BIFMA, AATCC, ISO,

FTC, CFR, etc.)

(是不是有充足的检测/实验设备来检测产品质量和成品的一致性,检测方法通常是i.e. BIFMA, AATCC, ISO, FTC, CFR, etc.)

15.Are the inspection defects charted, analyzed and ( ) Yes ( ) No

monitored to improve the problems encountered?

(检验失误是否被列图并分析和监察,以改善所遇到的问题?)

E. FINAL INSPECTION

(终检)

1. Do factory’s quality controllers perform any internal ( ) Yes ( ) No

final inspection on finished products?

(工厂的质量控制人员是否执行内部检查和成品检查。)

2. Are international, client’s or other approved standards ( ) Yes ( ) No

used?(用国际的、客户的或者其他的给予的检测标准吗?)

3. Are there written formal inspection reports and are they ( ) Yes ( ) No

properly filed to be traced to review quality of products?

(有正式的验货报告并且适当的归档跟踪分析产品质量情况吗?)

4. Are product drawings/specifications and/or samples ( ) Yes ( ) No

as well as packing instructions available for the

inspector from the QC or the engineering department?

(产品图纸、规格或者样品、包装说明,验货员可以从QC或者工程部门获得吗?)

5. Does factory perform internal mechanical tests during ( ) Yes ( ) No

production to safeguard the product’s quality and

are records kept to prove this?

(工厂在生产中是否为了维护产品的品质执行机械制的测试?是否有记录可以证实?)

6. Are these production test/inspection reports sent to the ( ) Yes ( ) No

QC supervisors for review and sign-off on a daily basis?

(产品测试或者检验报告是否送给质量监督人审阅并且作为日常记录档案)

7. Are adequate inspection and testing records maintained? ( ) Yes ( ) No

(是否保留适当的检验和测试记录)

8. Is the sampling size of products for final inspection ( ) Yes ( ) No

adequate enough to show the safety of products?

(产品是否有适当的尾检实验量足够说明产品的安全性)

9. Are there procedures in place that require acceptable ( ) Yes ( ) No

inspection reports to authorize shipment of the

products?

(产品的出货是否需要有通过检验的报告才可以出货的程序?)

10. Does factory perform a 100% check on functionality, ( ) Yes ( ) No

on at least one unit per production run and is the

current procedure sufficient?

(工厂是否执行了100 %检查功能,至少每次生产的一个单元,目前的程序进行是否足够?)

F. PACKAGING

(包装)

1. Is the packaging area clean, well organized and free of ( ) Yes ( ) No

contaminants?

(包装区域是否清洁,容易调配,能避免污染?)

2. Is there adequate safeguard to prevent one company’s ( ) Yes ( ) No

product from being packaged into another company’s

packaging or master cartons?

(是否有适当防卫措施避免一个公司的产品被包装到另一个公司的包装里或者硬纸箱里?)

3. Is there adequate control to prevent any defective or ( ) Yes ( ) No

rejected products from being packed into retail packaging?

(时候有适当的控制措施避免不良品或者废品混入零售包装中?)

4. Are semi-finished products well segregated from final ( ) Yes ( ) No

finished products in the packing area?

(在包装区域半成品和成品是不是被妥善的隔离开来?)

5. Are retail packaging materials properly stored and correctly ( ) Yes ( ) No

set-up prior to packaging beginning?

(在产品包装前,零售包装原谅是否妥当的储存?)

6. Are finished products packed into retail packaging ( ) Yes ( ) No

immediately, in order to avoid contact with dust and dirt?

(成品是否能及时的被包装到包装袋,以避免其接触灰尘和污垢?)

7. Is the method of counting product into the retail packaging ( ) Yes ( ) No

adequate to ensure accuracy?

(产品放入包装时方法是否能适当保证放入包装的计数准确?)

8.Do workers wear gloves or other protective clothing, if ( ) Yes ( ) No

necessary, in order to avoid contamination from dust and dirt?

(如果需要的话,工人是否佩带手套或者佩穿其他防护衣防尘土污垢)

9. Are packaging guidelines posted with all necessary ( ) Yes ( ) No

information for the correct packaging procedure?

(包装指引是否张贴为正确包装程序以提供所有必要的信息)

10. Are master cartons properly stored and correctly set-up ( ) Yes ( ) No

prior to product being packed into master cartons?

(主箱在产品放入之前,是否适当的储存和正确的放置?)

11. Are retail packaged units packed into master cartons ( ) Yes ( ) No

immediately, in order to avoid contact with dust and dirt?

If not, are they properly stored and protected?

(零售包装袋是否能很快就放入主箱,以避免灰尘和污垢,如果不能做到这样的话,包装袋

是否能适当的储存并得到防护)

12. Is the method of product count into master cartons accurate? ( ) Yes ( ) No

(产品计数到主箱的方法精确吗?)

13. Is the current procedure acceptable to avoid the possibility of ( ) Yes ( ) No

shortages or incorrect product in the master cartons?

(当前避免可能有一些不良品进入主箱的程序有可行性吗?)

14. Are packed master cartons stored in a warehouse or a ( ) Yes ( ) No

covered area to avoid sunlight and moisture?

(主箱是否储存在仓库或者隐蔽地方以防止日晒和潮湿?)

15. Is the product or packaging marked with a date code or ( ) Yes ( ) No

lot code to trace production?

(产品或者包装标志是否有日期代码或者标签代码便于跟踪?)

16. Does the factory have a system to verify the product ( ) Yes ( ) No

packaging and shipping marks are correct?

(工厂是否有体系去核实产品包装和箱唛正确与否?)

G. NON-CONFORMING MATERIALS

(不合格的原料)

1. Is there proof and/or documentation that non-conforming ( ) Yes ( ) No

material or products are properly identified and segregated

at all stages?

(是否有证据或者文件记录不合格的原料或者产品是否在全部货物中

被适当的鉴别并且被隔离)

2. Are adequate records maintained to show the status or ( ) Yes ( ) No

disposition of non-conforming materials as well as any

inspections of reworked product/components/material?

(是否是适当的记录保持指示不合格原料的状况或者部署,包括检验后

返工产品/原料/配件)

3. Are scrap materials or products handled satisfactorily? ( ) Yes ( ) No

(废料或者废品处理的觉得满意吗?)

4. If reclaimed materials are used, is there adequate ( ) Yes ( ) No

identification and checking to specification?

(如果再声的原料被利用的话,是否有适当的鉴定或者检查用于规范其使用?)

5. Can the factory demonstrate how they handle the ( ) Yes ( ) No

non-conforming materials such as products that fail to

meet specifications or mechanical tests?

(工厂可以证明他们是如何处理不符合规范或者不能通过测试的不合格的材料吗?)

6. Is the overall policy of treating non-conforming material ( ) Yes ( ) No

effective?(处理不合格原料的方针是否都有效?)

H. COMMUNICATION, DOCUMENTATION CONTROL AND WORK MOVEMENT

(沟通,控制性文件,运作)

1. Does factory management and key staff understand and ( ) Yes ( ) No

speak English sufficiently to enable direct communication with Staples?

(工厂经理和关键人物是否能流利的和Staples公司进行英文沟通?)

2. Is there an adequate and formal system for receiving ( ) Yes ( ) No

purchase orders, tooling and equipment?

(是否有一个适当的或者正式的接收订购单、模具或者设备的体系?)

3. Is there an adequate and formal system for receiving and ( ) Yes ( ) No

applying drawings, procedures, design change, etc. correctly?

(适当的或者正式的接受图纸、设计变更、程序的体系是否恰当?)

4. Are approved drawings and specifications filed and used ( ) Yes ( ) No

properly and are changes traceable?

(经核准的图纸和规范是否被归档并且妥善使用,修改后也可以有据可循?)

5. Are drawings, records and specifications easily available ( ) Yes ( ) No

that reflect an adequate history of the product?

(图纸、记录和规范是否能方便获取来反映产品适当的信息?)

6. In the case of authorized subcontracting, does factory ( ) Yes ( ) No

provide adequate supervision and specifications to ensure the

compliance to the requirements of client’s standards?

(在该产品授权外包,是否工厂提供足够的监督和规范,以确保遵守的要求,

客户端的标准呢?)

7. Does the factory have clear instructions to all employees ( ) Yes ( ) No

allowing them to stop production if they notice products

do not meet the established standards?

(工厂有如果发现不符合已制定标准的产品允许工人停产的明确指示吗?)

8. Is technical information clearly identified and are there ( ) Yes ( ) No

adequate controls in place to safeguard these?

(技术信息是否明确界定,并且有适当控制到位措施来防止技术泄露?)

9. Does the factory realize that all technical information relating ( ) Yes ( ) No

to the client’s projects is confidential?

(工厂了解所有的技术信息关系到客户项目的机密性吗 ?)

10. Does the factory notify their clients immediately to advise ( ) Yes ( ) No

and discuss any failures found on their projects?

(请问在项目中,工厂是否通知他们的客户立即提供意见和讨论任何故障)

I. HANDLING OF COMPLAINTS

(投诉处理)

1. Are customer complaints handled by management? ( ) Yes ( ) No

(消费者的投诉是否能得到处理?)

2. Does the factory have a formal process for handling ( ) Yes ( ) No

customer complaints?

(工厂是否有正式的程序来处理消费者的投诉?)

3. Are the complaints analyzed for their root causes ( ) Yes ( ) No

and Corrective Action Reports (CARs) created to

document the resolution?

(消费者的投诉抱怨是否被分析其产生根源并为此报告文件决议?)

4. Are corrective and preventive actions taken to eliminate the ( ) Yes ( ) No

non-conformity?

(矫正和预防性的措施是否能避免一些投诉?)

5. Is the corrective and preventive plan communicated with the ( ) Yes ( ) No

customer?

(矫正和预防性的措施计划是否于消费者交流?)

6. Are there adequate traceable handling of complaint records? ( ) Yes ( ) No

(工厂是否有适当的可以查询的处理消费者投诉的记录?)

7. Do records show that the corrective and preventive actions ( ) Yes ( ) No

are properly conducted and monitored to show effectiveness?

(记录是否显示矫正和预防性的措施被适当的进行并监控来显示其有效性?)